An article in

Design News says a new type of 3-D printing has been used to produce highly porous lithium-ion battery electrodes that will provide a higher charging rate and greater energy density in future lithium-ion battery cells.

It says current commercial lithium-ion batteries can be considered two-dimensional, with electrodes that are parallel to one another (during charging and discharging, lithium ions flow from one electrode to the other through the

electrolyte that separates them).

Regardless of the battery configuration, the basic architecture of parallel electrodes is the same.

A battery’s capacity is related to the total amount of active material that participates in the electrochemical reaction.

With solid planar electrodes, the distance the lithium ions can penetrate is limited. One solution is to make the surface of the electrodes very large, but this results in batteries that are heavy and of a size that makes them difficult to package in small-scale personal electronic devices — or even electric vehicles (EVs).

However, with their increase in electrode surface area, three-dimensional porous electrodes provide an increase in the participating material.

Researchers have examined foams and other porous materials for this application; they have also looked at 3-D printing.

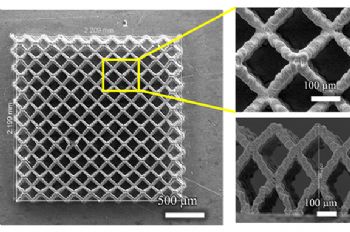

A new type of 3-D printing — one using the deposition and build-up of individual droplets into three-dimensional structures — is now being used to create experimental 3-D printed electrodes.

It is the work of Rahul Panat, associate professor (mechanical engineering) at Carnegie Mellon University in Pittsburgh, Pennsylvania.

Using the method developed in his lab, the researchers are able to 3-D print structures with complex geometries that are impossible to fabricate using typical extrusion 3-D printing methods.

Professor Panat said: “In the case of lithium-ion batteries, the electrodes with porous architectures can lead to higher charge capacities, because we create a micro-lattice electrode architecture that allows the efficient transport of lithium through the entire electrode, while also increasing the battery-charging rates.”

The researchers used an Optomec Aerosol Jet 3-D printing system. “Because the droplets are separated from each other, we can create these new complex geometries.

“If this was a single stream of material, as in the case of extrusion printing, we wouldn’t be able to make them.

"I don’t believe anybody until now has used 3-D printing to create these kinds of complex structures.” Professor Panat estimates that the 3-D electrode printing process could be ready for industrial applications “in about two to three years.”