Derby-based

SYS Systems has reported a 350% surge in sales in the dental market, as thousands of patients take advantage of the power of additive manufacturing (AM). The company is working with an increasing number of clinics and laboratories across the UK to install

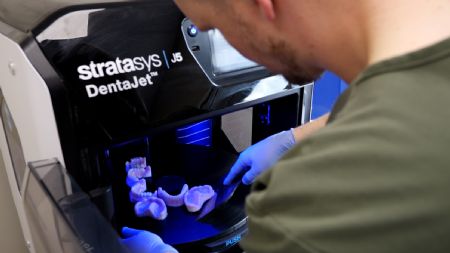

Stratasys’ J5 DentaJet printers to create removable dentures that deliver unrivalled aesthetic and functional results in half the production time.

The machines utilise patented TrueDent, a groundbreaking CE-marked resin that is extremely durable and, in a sector first, offers the ability to 3-D print multiple tooth and base shades simultaneously in a single full-colour, monolithic structure.

Matt Fulton, managing director at SYS Systems, said: “AM is revolutionising the way we make things, and the dental market is the latest to switch on to the benefits. It is a real win-win for dentists and labs. The 3-D printed prosthetics are versatile, highly durable and deliver the best aesthetics — all achieved in half the time it takes compared to the traditional route.

“Stratasys’ J5 DentaJet is the most advanced 3-D printer in this space and, when you combine it with the TrueDent resin, it is not a surprise that demand is soaring in the UK and Ireland. In fact, I think we are leading the way when it comes to sales of this machine in Europe.”

Complete turnkey solutionSYS Systems, which is the UK platinum partner of Stratasys, delivers a complete turnkey solution, including installation, service, maintenance, training and technical support. Experts from the company have been installing one J5 DentaJet every two weeks as more laboratories and clinics come round to its speed, functionality and aesthetic performance. The flexibility and power of the 3-D printer gives dental laboratories access to a solution to fit every need, whether that is monolithic dentures and temporaries to high-quality crown and bridge models.

Some of the first TrueDent fittings in Europe took place thanks to a groundbreaking partnership between SYS Systems and Prime Dental Laboratory, the latter a specialist in removable prosthetics and implant-supported dentures. The Ilkeston-based lab was one of the early adopters of the J5 DentaJet and the resin and this had a profound impact on both clinical outcomes and productivity.

Co-owner and clinical dental technician Tim Jackson (pictured below) said: “From the start of my career, I worked completely analogue, and I would set everything up by hand. In more recent years, we have invested heavily into the digital side of dentistry and have seen a big change with dentists wanting to use it as well.

“Digital dentures have sometimes been a little brittle in the past – not this TrueDent material, which I believe is the best 3-D printer resin on the market, surpassing everything I could have imagined strength-wise, as well as aesthetics. For example, we have thrown it down the corridor and even stomped on it and it is unbreakable.”

Significant time savingsHe continued: “Speed has also been important. Creating using an analogue method, we found that 18 dentures would take us around 12hr to make. Doing the same process digitally, we went down to about 6hr, and — now we have got the J5 DentaJet - we can also knock 1hr off that just on post-processing those dentures as well.”

One of Prime Dental’s closest collaborators is Zenith Dental Clinic, based in Nottingham. Principal dentist Dr Karan Maini was initially sceptical of digital methods, but has now fully embraced the technology and wouldn't go back. I had many reservations about digital dentistry in general. I was very much of the mindset that I wanted to do everything traditionally. I didn't even use a scanner at all.

“After I tried one for the first time, I thought that is quite good. Then you try another time, and it starts to get really interesting. Before you know it, I have been introduced to TrueDent and Stratasys through SYS Systems and here we are. Every denture I make is now a TrueDent denture. Digital adoption has had a big impact on our clients and our patients, with reduced chair time and patients being able to get their desired end result within a matter of days rather than weeks.”

Part of the Carfulan Group, SYS Systems is located in a £2.5 million Advanced Innovation Centre in Foston, near Derby. It has been a UK platinum partner for Stratasys since 2012 and is currently the leading supplier of Stratasys dental 3-D printers in Europe.