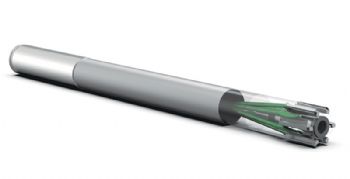

Fixed multi-bladed reamers are the means of choice, when high cutting values and short machining times are required.

Until now, the limitations of conventional manufacturing processes prevented the ideal delivery of coolant to all of the cutting edges on a reamer; the positioning of the coolant outlet for the cooling channels was always a compromise.

However, additive manufacturing has allowed Rugby-based Mapal Ltd (

www.mapal.com) to produce coolant channels of the optimum shape and position for reaming.

Thanks to special coolant outlets, the newly designed multi-bladed reamers of the MonoReam series now deliver the coolant precisely to the cutting edge, thereby ensuring optimum chip removal and cooling, as well as efficient lubrication of the cutting edge and the arc-land chamfer.

This in turn minimises abrasive wear of the arc-land chamfer and improves machining results — even when using minimum-quantity lubrication methods.

The MonoReam reamers are available in fixed (600), expandable (700) and adjustable (800) versions — and the three series are interchangeable.

Available as straight and left-hand fluted versions, as well as short or long versions, the new reamers are suitable for through holes or blind bores and are offered with cutting materials, coatings and cutting leads that are optimised for the material to be machined.