US-based Lockheed Martin is looking at ways to support long-duration deep-space missions, where astronauts will need a highly efficient and reconfigurable habitat.

Under a public-private partnership as part of NASA’s Next Space Technologies for Exploration Partnerships (NextSTEP) Phase II study contract, the company has completed the initial ground prototype for a cislunar living habitat that would be compatible with NASA’s Gateway architecture.

Cislunar will help NASA study and assess the critical capabilities needed to build a sustainable presence around the Moon and support pioneering human exploration in deep space.

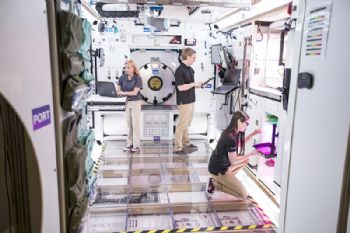

The full-scale prototype, or Habitat Ground Test Article (HGTA), is built inside a repurposed shuttle-era cargo container — called a Multi-Purpose Logistics Module (MPLM) — at Kennedy Space Center.

Using rapid prototyping and modern design tools, including virtual reality (VR) and augmented reality (AR), the team customised the interior of the module to accommodate a variety of tasks and the personal needs of astronauts.

The team also studied how to apply the advanced deep-space capabilities that are already built into NASA’s Orion spacecraft.

Through additional R&D funding, the NextSTEP team also applied mixed-reality technology to further refine the concept.

Bill Pratt, Lockheed Martin Space NextSTEP programme manager (

www.lockheedmartin.com), said: “Throughout the design and engineering process of this high-fidelity prototype, we have kept the diversity of missions in mind.

“By building modularity in from the beginning, our design can support lunar orbit and surface science missions along with commercial operations, all while accelerating the path to the Moon.

“Getting back to the Moon — and eventually Mars — is no small feat, but our team are mission visionaries. They have worked to apply lessons learned from our experience with deep-space robotic missions to this first-of-its-kind spacecraft around the Moon.”

Lockheed Martin has now sent the prototype to the NASA NextSTEP team for assessment, with NASA astronauts living and working inside the prototype, evaluating the layout and providing feedback.

The test team will also validate the overall design and will be able to evaluate all the systems and interfaces. Once NASA testing has been completed, Lockheed Martin will continue to optimise the prototype to prepare for future lunar missions.