Tamworth-based Industrial Tooling Corporation Ltd (ITC —

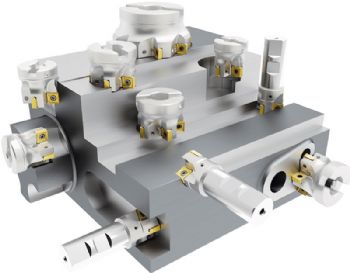

www.itc-ltd.co.uk) has extended its milling portfolio with the new VSM890-12 series of milling cutters from Widia.

The company says this is one of the very few eight-edged double-sided milling lines that offer a genuine 90deg milling capability and can undertake a variety of applications; these include face- and shoulder-milling, Z-axis plunging, contour plunging and 100%-radial-engagement slotting.

VSM890-series cutters are available with a 32mm-diameter Weldon end mill configuration, while the shell mill tool bodies are available in diameters from 40mm up to 250mm, and the cartridge face mill has a diameter of 315mm.

Each tool diameter is available as a coarse-, medium- and fine-pitch variant.

Coarse-pitch tool bodies in particular are recommended for low-spindle-power machines and unstable set-ups.

The 12mm inserts are available with eight of Widia’s premium insert grades and can achieve high removal rates on materials that include aluminium, steel, stainless steel, cast iron, titanium and high-temperature alloys.

Three insert geometries are available: ALP is the first choice for non-ferrous materials; ML is for stainless steel, light machining and finishing applications; while MM is the preferred option for machining steel, cast iron and high-temperature alloys.

Furthermore, with an integrated wiper facet and ‘super-positive’ rake angle on the inserts, the VSM890-series cutters produce ‘exceptional surface finishes and an efficient and smooth cutting action.

During the remainder of 2019, Widia will be extending the new range with the introduction of 7, 9 and 15mm inserts.