Version 2019.2 of HyperMill software from Bicester-based Open Mind Technologies (

www.openmind-tech.com) has a range of new features; these include high-precision 3-D finishing, five-axis tangent machining, high-performance turning and new CAD-for-CAM technologies.

Moreover, Open Mind has integrated more functions directly into CAM strategies (that previously required extra CAD steps) to further speed up programming.

The previous version of this software already featured high-precision profile finishing; 2019.2 offers a comparable

function for 3-D shape Z-level finishing (‘Smooth overlap’) that ensures ultra-smooth surfaces with tolerances in the µm range.

This saves time on post-machining finishing processes, particularly when applied to mould making.

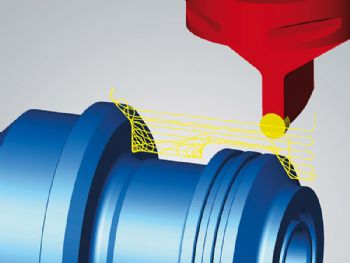

In HyperMill 2019.2, the HyperCAD-S function ‘Global fitting’ is directly integrated into the CAM strategy in five-axis tangent machining, allowing multiple faces to be joined into one face with defined ISO orientation.

The principle of using CAD elements for CAM programming is also applied, for example, for automatic face

extension; this sees the bounding surfaces automatically extended during programming to improve the edges of the machined surfaces — and the adjustments are made within the CAM strategy, without switching to the CAD environment.

With regard to performance, Version 2019.2 guarantees even greater process reliability, while tool-life monitoring makes it possible to restrict the use of a tool by the distance covered, the number of tool-paths or a time limit (if the defined limit is reached, a ‘retract’ macro is generated automatically, and the job ends).

Another enhancement is the addition of full-text searching to the macro database, allowing users to define machine and material groups as defaults, thereby making it easier to select macros.

A new function in HyperCAD-S allows the workpiece mass and centre of mass to be calculated with a material definition for solid, mesh and stock models.

Meanwhile, the ‘Undercut’ function allows undercut areas on components to be detected quickly and reliably; and the ‘Local curvature’ analysis function makes it possible to detect curvature radii on components.

The user can then determine the best-possible lead angles or tool radii for machining curved faces.