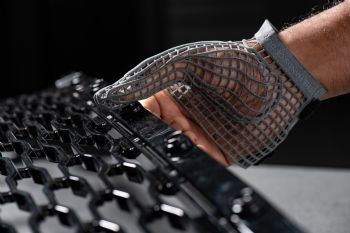

Engineers at Jaguar Land Rover are working on the next generation of protective workplace clothing — a lightweight 3-D printed glove that could help to protect employees from the threat of a musculoskeletal disorder.

The 3-D glove is designed for people working on production lines — perhaps fitting clips or fasteners to the chassis of JLR vehicles.

Engineers at Jaguar Land Rover’s Gaydon site, which is home to one of the largest 3-D printing facilities in the UK, saw an opportunity to use the company’s advanced manufacturing expertise to design and 3-D print a lattice-style structure that would provide support (and thereby reduce muscle fatigue), while also being flexible and comfortable enough to wear during an 8hr shift.

Using 3-D CAD software, they modelled designs in different densities using a variety of materials for testing.

Using the feedback from trials, they are now working on a second-generation prototype; this will include a foam pad made with a polymer that absorbs impacts when placed under pressure, making the glove suitable for those who fit parts using the palm of the hand.

Chris Noble, additive-manufacturing strategic engineer at JLR, said: “The well-being of our workforce remains our priority across all factories and facilities.

“Technologies like the 3-D printed glove allow us to use the world-leading expertise and equipment we have in-house to protect the hands of our manufacturing staff, developing equipment that will make Jaguar Land Rover a great place to work.”

The Jaguar Land Rover Additive Manufacturing Centre produces over 80,000 parts a year, including prototypes, design mock-ups, assembly aids and fixtures.

JLR can also 3-D print parts for production cars, with the Jaguar XE SV Project 8 one of the first vehicles to use them.