The latest version of the 4D_Additive software from CoreTechnologie GmbH (

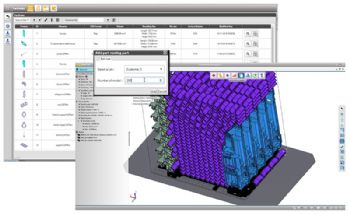

www.coretechnologie.com) includes a batch-nesting tool; with the help of thus new function, the CAD models stored in the system-specific database are ‘ordered as in a Web shop’ and sent to the printer.

The arrangement and orientation of the components (nesting) takes place automatically and does not require the user to have any 3-D printing expertise.

The tool is integrated in the software’s Partfinder, which makes it possible to locate and sort suitable parts for specific processes and machines.

CoreTechnologie says that the intelligent nesting tool ensures “optimal utilisation of the construction volume and 100% collision safety.

“For the fully automatic orientation of the parts on the build platform, functions are available that take into account criteria such as best-possible surface finish, minimum cost and space requirements, and minimal volume of the supporting geometry.

“Thereafter, the iterative calculation of the alignment takes place within seconds by just selecting parts from the pre-defined database and specifying the required quantity.”

The company also says that automated batch nesting offers particular benefits for powder-bed processes such as HP Jet Fusion, since the time saved by eliminating complex manual activities cuts part costs and the overall throughput time of the jobs.

“Users only have to select and set the respective quantity of the parts in a Web interface.

“Thereafter, the machine is filled automatically, so that an optimised number of components can be accommodated on the platforms.

“The relative density of a building volume can also be pre-defined, allowing for a sensible heat management.”