Tamworth-based Industrial Tooling Corporation (

www.itc-ltd.co.uk) will use

Southern Manufacturing 2020 to launch next-generation cutting tools (Stand H250).

The new innovations include the ITC 6071 series of solid-carbide stub-length end mills, developed specifically for the high-performance machining of steel and aerospace-grade alloys such as titanium and Inconel.

With an unrivalled reputation for aluminium machining, ITC has also extended its industry-leading line with the arrival of the new 3202 three-flute long series and the optimised length 3203 series of ball-nose tools.

Suitable for profiling and reaching difficult-to-access surfaces, the 3202 and 3203 offer manufacturers a complete solution for cutting aluminium and aerospace-grade alloys.

Also making its debut will be the 4204 series of long-length four-flute square-end milling cutters with a chip-breaker geometry.

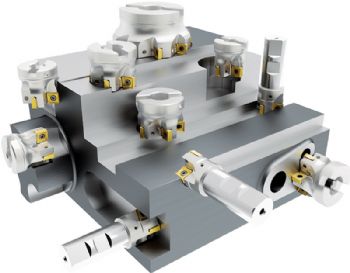

Supporting the new ITC product lines will be the latest arrivals from Widia, which ITC represents in the UK.

Visitors will be able to see the new VSM890-12 face and shoulder milling series, which is one of very few eight-edged double-sided milling lines with genuine 90deg milling.

This high-performance line offers superior metal removal rates on a complete range of materials when conducting face milling, shoulder milling, Z-axis plunging and contour plunging and 100% radial engagement slotting.

Meanwhile, the new VSM890 series is available with a 32mm-diameter Weldon end mill configuration, while the shell mill tool bodies are available in diameters from 40 to 250mm, with a cartridge face mill providing a 315mm diameter.

Also on display will be the Widia 70NS Victory X-Feed series of high-feed end mills now extended to cater for the machining of stainless steel and heat-resistant alloys.

The extension gives manufacturers that machine challenging materials a number of benefits.

It provides a significantly increased radial engagement when compared to ball-nose end mills, and a geometry revision has been optimised for circular plunging, 3-D machining, face milling and pocketing applications on heat-resistant alloys and stainless steels.

The new Widia range of 4U50 and 4U80 shallow-pitch roughing cutters will also be highlighted on the stand.

Suitable for stainless steel and high-temperature alloys, the solid-carbide end mills demonstrate consistent performance at higher machining parameters when conducting prolonged machining cycles on challenging aerospace-grade materials.

Designated as shallow-pitch roughing tools for high material removal rates in the aerospace industry, both series are available with four or six cutting edges with a ‘harmonically designed’ flute geometry and the choice of a short cut length (4U50 series) for superior rigidity or a regular cut length (4U80 series), with both enhanced cutting performance and stability when conducting heavy-duty roughing.

ITC will also have a comprehensive display of existing product lines alongside the new product launches; BIG Kaiser tool-holding and clamping technology will also be on display.