The Welding Institute (TWI), based in Cambridge, a leading research and technology organisation, has opened a new heat treatment facility to provide support for both internal projects and work for over 6,000 members. The facility will be run in accordance with its ISO 9001 certification as well as the requirements set out in AMS 2750 Rev E (

www.twi-global.com).

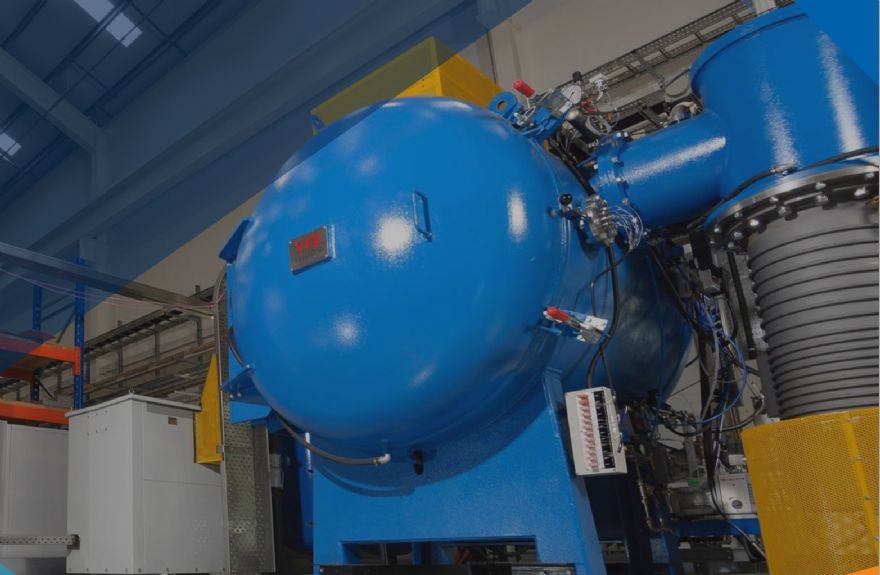

It includes a large commercial VFE vacuum furnace with a working thermal uniformity surveyed (TUS) area of 750 x 750 x 1000mm and a working surveyed temperature range of 250°C to 1,200°C. While the furnace usually runs with vacuum levels of <1 x 10-4 mbar, it can also be used in a partial pressure mode with gases such as nitrogen, argon or 5% hydrogen in nitrogen. To support the vacuum furnace, TWI also has an air furnace with a TUS working area of 500 x 500 x 550mm D and a working surveyed temperature of 150°C to 700°C.

This new facility provides several opportunities for our Members, including: business continuity when your equipment is not available, R&D work; process reviews and troubleshooting; pre-production work; and small batch work. It is already being used for core research programme work investigating the heat treatment of additively manufactured materials and another project investigating vacuum brazing of ceramic to metals. The heat treatment facility is also being used to conduct work for a PhD on the effect of hydrogen partial pressure on brazing and an EPSRC project investigating the use of high entropy alloys for brazing.

The heat treatment facility builds on its existing characterisation and testing facilities, covering work such as tensile testing, charpy testing, hardness testing and micro hardness testing.