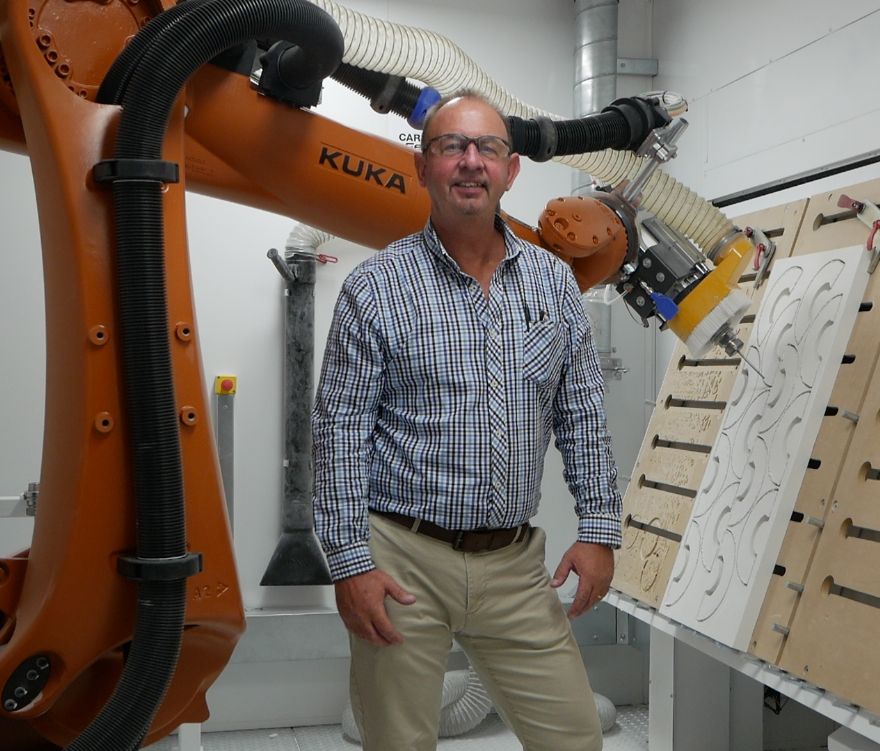

A company manufacturing industrial furnaces and ovens has switched from routing with a flat-bed machine to using a robotic cell designed and developed by CNC Robotics Ltd. This cell uses a Kuka robot arm (programmed with Alphacam and RoboDK software) to cut insulation material — at cutting speeds that are now up to eight-times faster.

Derbyshire-based Carbolite Gero Ltd uses various insulation materials — including Kerform insulation board, refractory brick and ceramic materials — to keep the temperature of its steel outer cases down to around 60°C, while the internal temperature peaks at 1,200°C.

The ovens and furnaces are used in a wide range of testing and heat-treating facilities in sectors such as aerospace, engineering, materials science, heat treatment, medical and bio-science — as well as in contract testing laboratories and universities investigating how products and liquids react in a heated environment.

The company was already using Alphacam — from Hexagon’s Manufacturing Intelligence Division (

www.alphacam.com) — to drive its three-axis Biesse router, but plant manager Nigel Holmes-Taylor says that the Kerform board (along with other insulation materials) produces a highly abrasive dust when cut, which caused considerable wear on exposed parts of the CNC machine.

“We came across robotic arms with a routing attachment, and decided that was the route to take.” He approached CNC Robotics, a UK robotics integration company that specialises in machining with robots.

An important issue for Carbolite was wanting to keep its existing Alphacam programs and integrate them into the robotic cell. Nick Parry — a systems engineer with CNC Robotics who subsequently led the development of the single enclosed robotic cell — said this would not be a problem.

Jason Barker, CNC Robotics founder and owner, added that when machining with robots, it is necessary to simulate the robot accurately. “Simulation is vital for checking correct posture, singularity, wrist and elbow, and axis limits. The importance of ‘what you see is what you get’ is critical; if it crashes on screen, it’ll crash in the real world. Using software such as Alphacam and RoboDK means you can correct all that before going anywhere near the robot

itself; and being able to convert the existing Alphacam programs that powered the router meant there was no down-time learning a new software. Carbolite was able to take its existing programs and redevelop them into the robotics world.”

Overcoming issuesAlphacam area sales manager Martin Measures explains how the simulation issue was overcome. “Tool-paths created in Alphacam are passed directly to a RoboDK interface within the software, which simulates the robot kinematics. RoboDK is a specially configured software development kit that outputs the co-ordinate cutting data to drive the robot. It means that we can see exactly what the robot is going to do before it processes parts.”

Mr Holmes-Taylor added that because Carbolite’s new robotic cell can move at up to 2m/sec, it provides a significant improvement over the previous manufacturing process. “Cutting speeds are far quicker on the robot than on the flat-bed router; and while the router was restricted to working in three axes, the robot arm effectively has six axes — but it can be ‘infinite’ in the way it operates.

“We take the part files from drawings produced by our engineering facility and import them into Alphacam. This brings all the cutting paths together and sends the program to the post-processor, then into the RoboDK module for simulating the movement of the robotic arm; and because Kerform insulation board comes in a variety of thicknesses and temperature grades, the robotic cell designed by CNC Robotics provides an additional benefit when compared with a flat-bed machine.

“Thanks to a special rotating table, we now have four positions on both sides of the bed, which means that we can cut the several types of board needed to produce a full unit at the same time. With the flat-bed machine, we could only deal with one type of board at a time, so this gives us a four-to-one ratio of cutting it quicker; and in some circumstances, it’s up to eight-times faster.

“Furthermore, all the abrasive dust created during the cutting process is contained within the cell and drawn out through an extraction system, thereby ensuring that the overall environment is much cleaner.”

A further bonus is derived from the fact that Alphacam can produce a full description of what needs to be loaded into each material storage location. Software developed by CNC Robotics displays the PDF generated by Alphacam, allowing the operator loading the machine to know the next material to load and where it needs to be located.