Germany-based

Gabo Stahl GmbH, a leading European supplier of high-quality steel products, offers a wide variety of steel grades and is able to deliver quickly thanks to its large stock and in-house processing facilities. To enhance its manufacturing capabilities further, the company recently installed an automated solution for the end machining of round steel. Sawn round steel bars with lengths of 9mm are just as much a part of Gabo Stahl’s portfolio as round steel bars with a length of 6m. There is a large customer base, and the steel products it distributes are used for a wide range of applications – from use in electrical and hydraulic parts production to large bolts for wind turbines.

Gabo Stahl is not only a steel trader, but also a steel processor. The company based in Essingen near Aalen was looking for the right system to machine the ends of all round steel bars with a diameter of 30-100mm and a length of 300-2,000mm.

Gabo Stahl CEO Thorsten Maier said: “We like to supply our customers with the primary material ready for use and undertake as much preparatory work as possible. At Gabo Stahl, these products are not usually manufactured in large quantities — business is mainly dominated by small runs.”

Simple operationHe continued: “Our production equipment has to be able to work just as flexibly as we do. Although we perform machining tasks for our customers, we don’t have any trained machinists working for us.” Therefore, in addition to the requirement to handle different dimensions and steel grades, there is also a need for the simplest possible operation.”

Markus Fuchs, purchasing manager at

Mössner, a machine manufacturer that is also based in the greater Aalen area, said: “That’s a typical case for us. Mössner is a specialist in the field of automated special-purpose machinery. Customised solutions are an area that tooling company

Mapal is also familiar with. Mr Fuchs continued: “Mapal is our go-to partner, we work closely together and receive quick, straightforward support, and this is helped by our geographic proximity.”

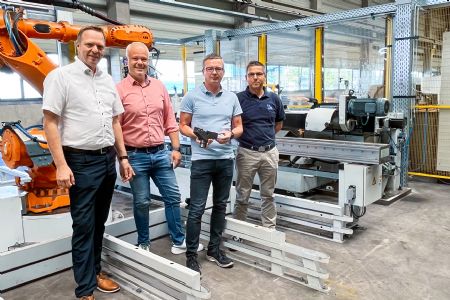

Mapal and Mössner collaborated for around eight weeks to design the system that is now installed at Gabo Stahl. Marc Wagner, technical consultant at Mapal, said: “The tool for facing, chamfering and centre drilling different types of steel and diameters proved to be a major challenge.” The various steel grades were the main source of development work. The engineering steels and tempering steels to be machined are usually specified by Gabo Stahl’s customers in terms of chemical composition and mechanical values.

Mr Fuchs said: “We get everyone round the table, work things out, think creatively and find joint solutions. Once the right tool has been found and designed, we build the rest of the machine around it.”

Optimum solutionThe team found the optimum solution was a milling tool with cartridges and a centre drill. Alexander Schulze, an application engineer at Mapal, said: “We are able to reliably machine the many different workpiece materials and workpieces with the same coated indexable insert. The cartridges can be used to quickly and easily set different diameters for the chamfer on the workpiece.”

This requires no specialist knowledge and can be easily done after a short briefing. Different centre drills made of coated solid carbide in various diameters are clamped into the tool itself using easy-to-operate clamping sleeves. Here, the solution lay in the special geometry. Mr Schulze explained: “We have developed a tool that precisely performs both chamfering and facing as well as centring. Not just on one side of the round steel bar, but on the other side at the same time with a similar tool.”

Mr Maier continued: “The system from Mössner is a great asset for us.” Before production started with the new machine, all machining operations were performed by hand. Gabo Stahl thus not only saves a huge amount of time with machining, but also ensures the consistently high quality of the machined ends. The system also saws, measures, marks, demagnetises and packs the workpieces — it is in fact an all-inclusive package supplied by Mössner and Mapal. The staff who work with the machine every day are also impressed by how easy it is to use and by the ability to switch over to new components quickly and in a straightforward way.

Mapal works on projects with Mössner all over the world. For example in Mexico, where many car manufacturers and suppliers operate plants and rely on the combined solutions of both companies. Mapal has already designed a separate tool range for Mössner, which is specifically tailored to the manufacturer’s machines. So further joint projects are already in the pipeline including in sectors other than the automotive industry.