When the latest version of the ProtoTrak control system was introduced by XYZ Machine Tools (

www.xyzmachinetools.com) it brought with it a range of benefits to improve programming efficiency and ease-of-use, all based around the 15.6in touchscreen that put the many advantages of ProtoTrak at the users’ fingertips.

As with all successful products, to maintain their advantage development has to be continuous, users of the control on XYZ RMX bed mills can further simplify the programming of complex parts, including islands in pockets.

New and existing users can take advantage of the islands in pockets feature by using the optional DXF converter, which can be added at time of ordering the machine or as a straightforward retrofit for existing XYZ RMX bed mills.

With this option installed, it is a simple process of importing the DXF file into the ProtoTrak RMX control and the creation of the island program, for single or multiple islands in pockets, is created in the same easy way as any other machining feature in ProtoTrak.

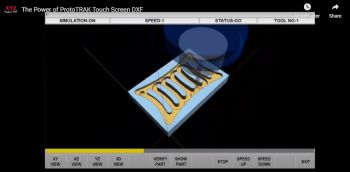

The program toolpath can be verified on-screen, with an estimated cycle time and for further reassurance a 3-D solid model of the machined part can be generated.

Nigel Atherton, XYZ Machine Tools managing director, said: “ProtoTrak remains at the forefront of programming technology for use on our XYZ bed mills and lathes and continues to be the ‘go to’ control for those making the step from manual to CNC operation, and for those looking for a machine/control combination that can simplify their manufacturing processes.

“The control’s popularity has continued through the current Covid-19 pandemic, with customers continuing to order and take delivery of ProtoTrak-controlled machines — over 250 machines have been delivered in the past six months.”