Radan 2021 (

www.radan.com) from Hexagon’s Manufacturing Intelligence division offers further advances in software for sheet metal processing in areas that include CAD/CAM, tubes, bending, quoting and the CAD for CAM modelling tool.

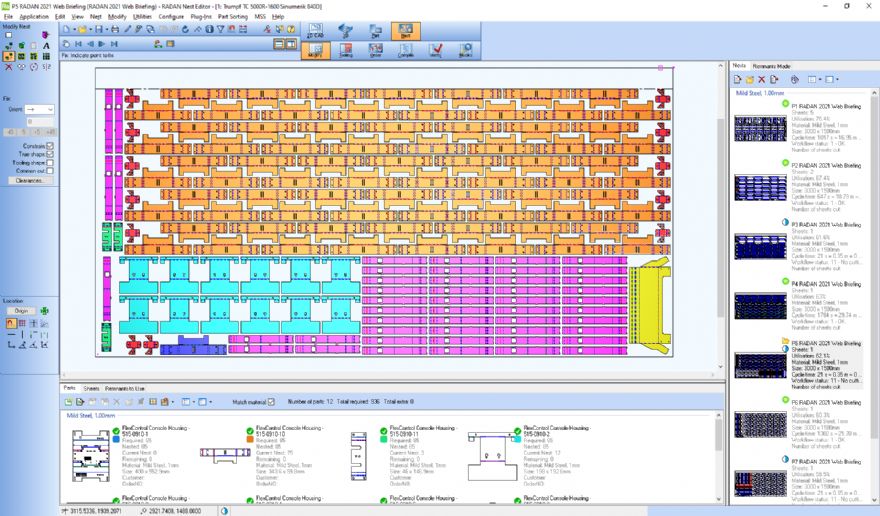

Product manager Olaf Körner says that, for manufacturers operating punching machines and wanting to optimise batches of nests, set-up sheets can now be automatically generated and sent to each machine, saving around 50min in an average day of producing up to 80 nests.

“The NC code for the job goes to the machine, and the set-up sheet to the operator — all via a simple tick box. The sheet is always up to date, with no chance of omissions or errors.”

Meanwhile, the Radm-ax/Radtube module in the latest release overcomes the issue of hazardous holes that result when pieces of metal are left in a ‘dangerous position’ after a hole has been cut in a tube. Extra cuts can now be carried out, dividing the slugs into smaller chunks, which fall out more readily.

There are also three updates to multi-part nesting: the ability to import order and job numbers, which include details of which order the parts belong to, so they can be kept together for assembly; the ability to start manufacturing automatically from a full assembly, without needing to take individual shapes, sizes or material into consideration; and the addition of a new

Tube Purchasing Report that details what materials are required for a job — either from stock or needing to be purchased.

Furthermore, common-line cutting can now be carried out even if the ends have cut-outs in the design.

The Radbend module now offers improved collision checking during automatic sequencing; it also reduces handling when calculating sequences automatically by reducing the need for tool and part rotations— and the tool editor now shows important additional information by default, making it more user-friendly.

A development in Radquote means that cutting strategies can now be specified on a part; the software asks how the parts are to be cut — such as whether oxygen or nitrogen is required for a laser part, and what finish is required, as these factors affect costs.

In addition, Radan 3-D drawing files can be added to the quote, complementing its ability to read directly from CAD files — and a 2-D shape can now quickly be modified in Radraft and updated in Radquote.

A number of items of new and enhanced functions have been added to the Designer module.

For example, it now indicates bends where the design radius differs from the expected resulting radius when using V-width as the unfolding method — and feedback is now provided on overlapping unfolds.

Another new function adds ‘watertight corner reliefs’, showing in 2-D what it will look like to make in 3-D.