Kent-based HV Wooding Ltd (

www.hvwooding.co.uk) has produced heater plates for ventilator humidification chambers since 2004, but with the advent of the coronavirus pandemic has seen its annual order for 160,000 double overnight as demand for ventilator components has skyrocketed.

At the same time, the company was also asked to prototype three components for a ventilator as part of the Ventilator Challenge UK consortium which was set up by the Government in March to give the UK the capability to domestically mass-produce ventilators.

A consortium of UK industrial, technical and engineering businesses from the aerospace, automotive and medical sectors have collaborated together to prototype and manufacture two agreed designs of much-needed ventilators, based on existing technologies.

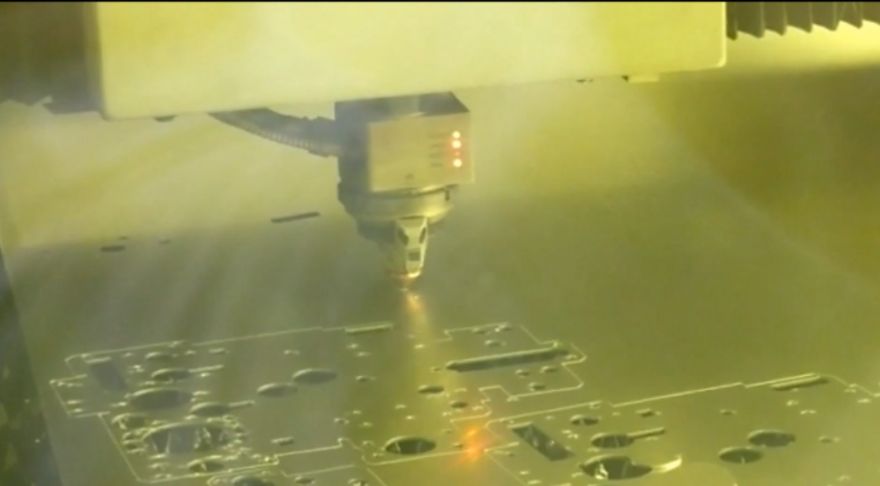

As a member of the consortium, HV Wooding has been able to use its expertise in CNC laser cutting, programmed with Radan sheetmetal software (

www.radan.com), to great effect.

Paul Allen, HV Wooding’s sales director, said that while its core business is in the energy sector – making parts for renewable energy, power generation, conversion and distribution, and electrical switchgear – it has also manufactured components for the medical sector for 30 years.

HV Wooding’s customer Williams Advanced Engineering has been working on prototyping a new version of a Smith's Group ParaPAC 300 ventilator and required three aluminium components for the chassis and front plate.

He continued: “We created and produced five off, over the weekend. They were very well received, and we then moved to the next stage, which was to get the parts to conform 100% to requirements and into full production.

“Radan software meant we could quickly condense all the necessary up-front work which would normally take at least a month, into just a few days, and we successfully manufactured and delivered 2,000 sets of each of the three components in a very short time frame.”

Mr Allen said Radan played a major role in meeting the challenge. “We run Trumpf fibre laser technology and use Radan for assisting with our quotation process, as well as producing the parts from the DXF facilitating the programming, nesting and cutting.

He added: “It meant we could put multiple parts into the program, and it nested everything in the most cost-effective and efficient way.”

HV Wooding have been able to keep its factory open and operational throughout lockdown, but Mr Allen says a number of measures have been put in place to ensure the health and safety of its workforce, including social distancing and daily temperature testing.

He concluded: “A lot of effort has gone into making sure our shopfloor workers have the correct equipment and space, while a number of the office staff are working from home.”