Founded in 1962 as a specialist sub-contract gear-cutting business, Basildon-based ESL Engineers Ltd quickly gained a reputation for its technical expertise and for the quality of its output.

Significant levels of organic growth over several decades and strategic company acquisitions have allowed ESL to considerably increase its production capacity and to expand its range of manufacturing specialities.

In addition to gear-cutting, the company produces a diverse range of precision-machined components at its 30,000ft

2 premises. Accredited to ISO9001 and AS9100D and having many aerospace approvals, ESL has developed partnerships with many leading aerospace companies and has applied its aerospace manufacturing capabilities and quality standards to other equally demanding sectors.

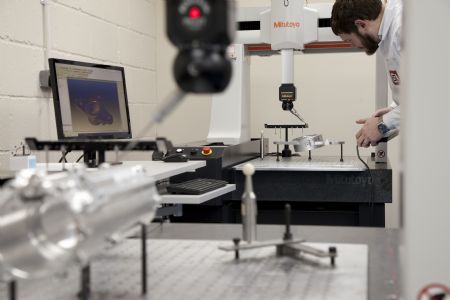

To enable the company’s busy quality department to maintain its exacting quality standards and to speed up its inspection work, ESL — a long-time user of CMMs from Andover-based Mitutoyo UK Ltd (

www.mitutoyo.co.uk) — recently purchased a newly launched Mitutoyo Crysta-Apex V CNC CMM.

ESL quality engineer Dave Humphrey said: “Mitutoyo continually develops its CMM technology, so to stay at the forefront of inspection advances, we periodically replace our older Mitutoyo CMMs with the latest models. This policy has allowed us to take advantage of the most recent CMM developments and uphold our meticulous quality standards.

“We recently needed to further increase our inspection capacity; and having installed a Mitutoyo Crysta-Apex S CNC CMM less than two years ago, we contacted Mitutoyo UK to find out about the technical improvements made to the new V range; and although we looked at other makes of CMM, we found this new Mitutoyo machine to be the most attractive option in terms of capabilities and price — and placed an order.

“In fact, so new is the Crysta-Apex V range that we were the first company in Europe to take delivery of one of these CMMs. This new machine and our existing Mitutoyo CNC CMM are now located in our environment- and temperature-controlled quality department; and because the new machine is an evolution of its predecessor, it was easy for our three quality department staff to quickly become accustomed to its operation, and they can readily swap from machine to machine.

“Our Crysta-Apex V and our older Mitutoyo CMM are the mainstays of our quality provision, and we use them to perform first-off, in-process and final inspection routines — plus a multitude of other high-precision measuring and inspection tasks — making full use of their FAI and SPC reporting capabilities.

“When required, we can supply these reports to our customers — and archive all traceable inspection data. In addition to inspecting one-off parts, we can load multiple smaller components onto the CMMs’ beds, recall the relevant programs and undertake fully automated CNC mass inspection routines.”

As the successor to the popular Mitutoyo Apex S CMMs, the new Crysta Apex V machines can perform very accurate measurements at high speed; and having a ‘high resistance to environmental conditions’, they can also be used on the shopfloor.

Furthermore, given the advent of ‘Smart Factories’ and the Internet of Things, Crysta-Apex V CMMs are equipped with Mitutoyo’s recently introduced Smart Measuring System technology. This allows the online monitoring of CMMs’ operational status and the capture of records related to key parts.