Bicester-based

KW Special Projects (KWSP), a Silverstone Technology Cluster member, has partnered with London-based

Respolab to create what is believed to be a revolutionary new design in face mask and shield PPE systems.

Final trials of the Respolab design are now underway and a pre-production prototype is now being tested by the British Standards Institute (BSI) for validation.

Pending CE certification to EN166 and EN1827, the device could go into series production. Furthermore, manufacturing is set to be done in the UK in a boost to the nation’s own PPE supply chain.

Kieron Salter, KWSP managing director, said: “The manufacturing of production product is mainly injection moulding so that could be a call to action for businesses in the supply chain.

“Who knows, maybe it can be done in the STC region? Certainly, we see this as an opportunity for UK manufacturing to do something itself, rather than the UK being reliant on sourcing PPE from overseas.

“The original design was the brainchild of BDI – our bit has been using the strength of our own resources and our additive manufacturing (3-D printing) expertise, to rapidly develop the products and build production ready prototypes. We have also found some interesting cross sector technology transfer opportunities such as the innovative filter system.”

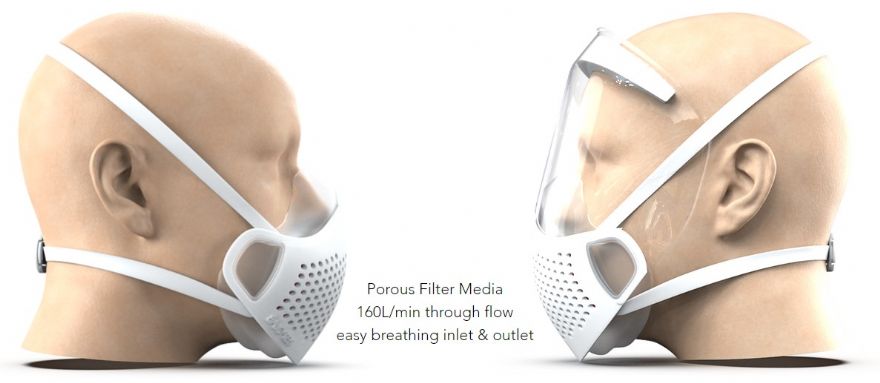

In short, Respolab is a valve-less full face or half face ‘FFP3’ mask that, according to Mr Salter, addresses current design flaws in protection against viruses, dust and allergens. It can also be re-used and is manufactured using re-useable materials.

Kieron explained that longer-term thinking had been applied rather than simply trying to find a short-term fix for healthcare professionals and patients during the Covid-19 pandemic.

He added: “Covid-19 has resulted in some big changes in people’s habits, whether that be in healthcare services, other consumers and the wider general public, so this has the potential to be quite big into the future on a global scale.

“We are confident that Respolab moves face mask and shield design to a whole new level, particularly in terms of protection for the wearer, and sustainability.

“With the full CE marking being close, we are now lining up the supply chain and distribution network. The aim is very much to go into production on an industrial level with our own manufacturing and via licensing deals as well.”