R&D tax specialist

Catax has revealed that Wolverhampton-based

www.sfeuk.com Surface Finishing Engineering (SFE) — a mechanical engineering specialist — has been rewarded with £357,804 of Government tax incentives after ‘revolutionising’ the way that aircraft engines are cleaned.

SFE, a leading provider of turn-key solutions for surface treatment lines where special chemical processes are required on metallic parts and components, works closely with aerospace and aviation companies world-wide.

The company received the money back from the Government in the form of R&D tax credits for significantly reducing the time an aircraft engine is ‘off wing’ for maintenance, repair and overhaul (MRO) work.

Engines that power a Boeing 777, for example, are 2m in diameter and comprise hundreds of different components — from compressors and fans to combustion chambers, nozzles and pipework; and during their time in the air, these high-bypass turbofan engines draw in sand, dirt and airborne debris.

It typically took 30 days for aircraft engines to be periodically disassembled, chemically cleaned, inspected under UV light and then reassembled.

SFE was asked by one of its customers to come up with a way of reducing the time it takes to clean the engines so that aircraft could get back in the air sooner. The company first experimented with speeding up existing processes, but that did not achieve the required efficiencies.

This was partly because the most time-consuming part of the engine to clean is the main high-pressure turbine — the largest section of the jet and extremely heavy — necessitated that a lot of the cleaning be done manually by dipping individual components into treatment tanks.

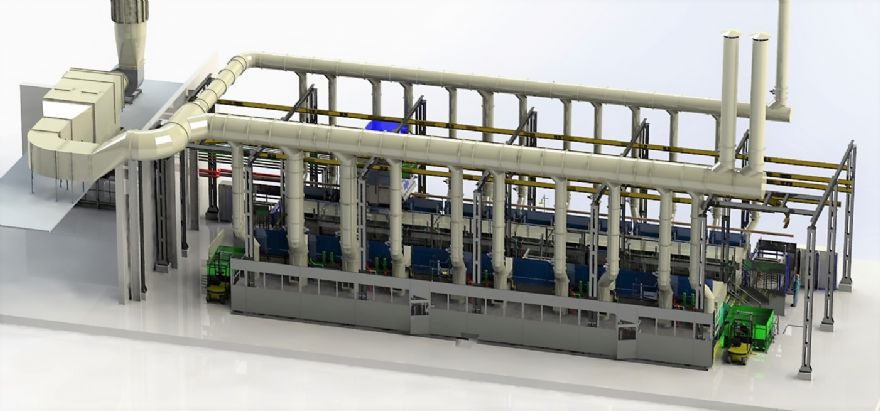

However, SFE decided to create a completely new piece of machinery that could halve the cleaning time to 14 days by accommodating the turbine as an assembly, thereby obviating the need for it to be taken apart.

The company worked closely with its client to develop a bespoke solution that uses proprietary chemicals with the assistance of “advanced multi-directional ultrasonic soundwaves”; these cause cavitation and allow the chemicals to work more effectively and efficiently.

Vic Delveir, SFE’s business development director, said: “We had never claimed R&D tax credits in the past and Catax worked closely with our accountants to collect all the necessary evidence. At first, I was a bit sceptical because I hadn’t been aware that this tax incentive was on offer at all.

“It did not take long in my discussions with Catax for them to demonstrate that our innovations would qualify and I was somewhat surprised when the scale of the benefit became clear.

“We received the news only two weeks after the Government announced a nation-wide lockdown due to the Covid-19 pandemic, so it was perfect timing.

“A sum of this magnitude is going to help us navigate what is going to be an extremely challenging time for the aviation industry.”