Established more than 30 years ago, Mildenhall-based sub-contractor

CTPE uses three- to five-axis machining centres plus fixed-head and sliding-head CNC lathes to make complex high-precision components — mainly for the scientific, medical, electronics and defence sectors.

The latest addition to the companys plant list is a Biglia B 620 YS fixed-head turn-mill centre with a Y axis and a sub-spindle, which are both options.

Supplied by Kenilworth-based

Whitehouse Machine Tools Ltd, this is the first lathe from the Italian manufacturer on the sub-contractor’s shopfloor — and only the second example of this new model to be installed in the UK, following its launch at the

EMO 2019 machine tool show in Hanover.

The machine has a 30kW 4,500rev/min direct-drive main spindle with a capacity for 70mm-diameter bar, which is fed from an LNS Alpha SL65 short-bar magazine. That said, billets up to 360mm in diameter can be manually loaded for turn-milling.

The B 620 YS is meeting a five-fold increase in demand for a tight-tolerance aluminium connector that forms part of medical equipment needed in ‘the fight against Covid-19’.

CTPE has been making this component for the past 15 years on a Y-axis lathe with a single spindle, which meant that the part had to be re-fixtured by hand on the same machine for a second operation, after which manual deburring was necessary.

The component is now produced in larger volumes much faster, as well as more accurately and consistently, in a single hit on the Biglia; and with deburring included in the machining cycle, 600 can be shipped every week. This increased supply rate started at the beginning of April and is likely to continue through to September.

Alex Taylor, CTPE’s operations director, said: “The reason for buying the lathe was a significant uplift in orders from the medical industry in general, not only for the connector part. However, we were also on the look-out for a machine capable of raising our turn-milling productivity across the board, including that of larger components from billet.

“The Biglia provides a good balance for both types of turning, machining components up to 620mm long; and with its sub-spindle, this machine is ideal for one-hit machining. It has been operating 12-15hr every day since it was installed, and it runs really well unmanned. Indeed, the machine is sometimes left for 10hr without any manual intervention.”

Eliminating scrap

Mr Taylor went on to say that the margin for error is much greater when a component is being handled more than once, and that with the previous two-hit production route — plus deburring — some parts had to be scrapped.

“That is not the case now. After a brief warm-up period, the Biglia maintains size well, easily holding diameters on the connector part within ±10µm — and with a good surface finish. The part has many milled features, so the Y axis is invaluable.”

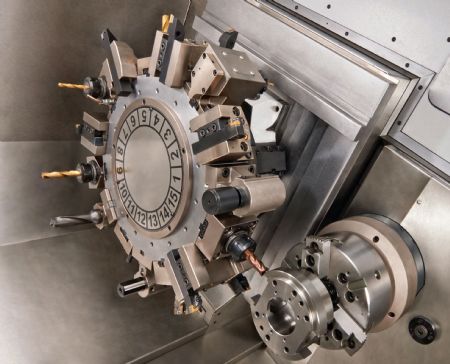

The machine installed in Mildenhall has 15 turret stations, all of which are powered by a 13kW 6,000rev/min motor. Up to 30 cutters can be in the machining area at any one time, although 12 tool positions in the turret is optional to avoid the risk of interference if large cutters need to be used.

Mr Taylor opted for the larger number to avoid retooling when machining complex parts. Additionally, extra tools can be set, ready to tackle a range of different jobs without having to repeatedly exchange cutters.

Unlike some twin-spindle lathes, the B 620 YS has a full C axis on the 15kW 5,000rev/min direct-drive sub-spindle, as well as on the main spindle, making it easier to plan cycles so that machining is better balanced at either end of a component (minimising cycle times).

Mr Taylor added: “The lathe is capable of heavy-duty cutting, as well as high-precision machining. It incorporates a mixture of box ways in the X and Y axes and a linear guide rail in the 620mm Z axis. A slight compromise on rigidity in this axis is more than offset by the higher feed speed and 30m/min rapid-traverse rate, rather than 18m/min available in the box-way axes.”

Some programs are prepared off-line, while simpler parts are programmed at the touch-screen Fanuc i-HMI control. The ‘handling’ of components as they come out of the machine was an important consideration to maintain a ‘crisp and undamaged’ surface finish, so CTPE specified a conveyor at the front of machine to ensure reliable parts handling during unattended operation overnight, with components dropping into a padded box.

Mr Taylor concluded: “We have been dealing with Whitehouse Machine Tools since 2016, when it installed the first of three Brother Speedio 30-taper machining centres, but the Biglia brand stands on its own merit.

“I visited the factory in northern Italy in 2019 to see the machines being built, and it gave me every confidence that CTPE was making the right decision. Biglia specialises in making CNC turning centres; indeed, it only makes this one type of machine — around 500 a year.

“The way the machines are put together and the quality of the component parts place them in the high-end category, so they compete with the best of the Japanese and German makes. Today, the installed base of Biglia lathes in the UK and Ireland is around 700.”