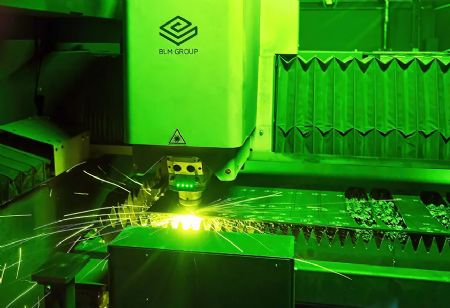

BLM LS7 6 kW fibre-laser cutting centre on the shop floor at Olicana

BLM LS7 6 kW fibre-laser cutting centre on the shop floor at OlicanaYorkshire-based

Olicana Products has for many years prided itself on providing a top-quality, high-volume, CNC tube laser cutting and bending service, as well as robotic welding and powder coating, for customers involved in the manufacture of mainly commercial seating, but also medical, education and bathroom products.

The only items bought in were flat metal components that constitute a relatively small part of most fabrications. However, fast forward to today, and even that function has been integrated into the Ilkley factory with the installation in April 2024 of an LS7 flat-bed, fibre-laser cutting machine supplied by Ampthill-based

BLM Group UK, a subsidiary of the parent machine-manufacturing company in Italy.

It was disruption to the supply of sheet metal components from external sub-contractors during the Covid-19 pandemic that first prompted Olicana’s management to consider bringing that type of production in-house as well. So, a second-hand, flat-bed, CO

2 laser cutting machine was initially purchased to manufacture the components. Successful implementation demonstrated that it was the right decision, so it was decided that a new, modern, fibre-laser profiling centre was needed for ongoing use. From four potential suppliers, a BLM machine was chosen.

Stephen Thorpe, Olicana’s technical director, said: “The BLM LS7 was selected due to it being a top-class machine, coupled with the fact that we have been using tube-bending machines from BLM since 2001 and have been very satisfied with both the equipment and the service they provide.”

First electric tube manipulatorHe explained that the first BLM tube-bending machine, an E-TURN 52, was capable of processing tube up to 52mm outside diameter. It was the first electric tube manipulator in the Ilkley factory, the pre-existing three being hydraulically actuated, and was able to execute a wide range of functions such as variable radius bending.

Pictured right: The latest BLM E-TURN 32 CNC electric tube-bending machine to be installed in Olicana’s factory

Pictured right: The latest BLM E-TURN 32 CNC electric tube-bending machine to be installed in Olicana’s factoryNotable also is that all-electric tube benders have better accuracy than their hydraulic counterparts and are more environmentally friendly. It is due to the absence of hydraulic fluid, which rises in temperature during operation, leading to thermal expansion, while they also have a tendency to leak.

Most significantly, however, the 15-axis E-TURN employs a double head with a novel swinging action, enabling both right- and left-hand bends to be undertaken in the same automatic cycle. It deskills the creation of highly complex tubular geometries and avoids the need for a second operation on the same length of tube, although for some applications that is not possible anyway.

Mr Thorpe advised that with the type of fabrications Olicana makes, the use of a tube bender that operates in only one direction would in practice, for many products, mean that two separate tubes would need to be processed and welded together. Depending on tube diameter and material, and whether the weld position was in an area of the end product that was visible and needed fettling and finishing, the cost of manufacturing the item could be as much as double.

Off-line VGP3D software simplifies operationSuch was the success of the E-TURN 52 installation that a further two machines, both new but of smaller, 32mm diameter capacity, were purchased in 2021 and 2023 directly from BLM in Ampthill. The machine supplier’s off-line VGP3D software simplifies operation of all three electric tube-bending machines. On receipt of a customer order and component drawing, Mr Thorpe simulates the bending sequence on-screen to detect any potential collisions or other problems. If issues are encountered, they are discussed with the customer and design changes — another key facet of the Olicana offering — are proposed before the program is finalised.

Pictured left: the BLM LS7 6kW fibre-laser cutting centre on the shopfloor at Olicana

Pictured left: the BLM LS7 6kW fibre-laser cutting centre on the shopfloor at OlicanaAfter the software has automatically generated the bending cycle, taking into account the tube material, diameter and wall thickness, it is rare that there is a need for the cycle parameters to be adjusted, according to Mr Thorpe. The program is simply sent over a network link to one of the tube-bending machines and production starts straight away.

The BLM E-TURNs incorporate innovative features to ensure that tight tolerances are held from the very first part, including compensation for tube springback and elongation. A checking fixture is made at the Ilkley factory for every new order and 100% inspection is employed to verify accuracy.

Drawing tolerance is generally surprisingly tight, typically within plus or minus one-fifth of a degree, sometimes requiring final manual tweaking of the computer-generated springback values. Mr Thorpe confirmed that a high level of quality is repeatably achieved and indeed is essential for trouble-free robotic welding during the next stage of production.

Tighter control on productionERW (electric resistance welded) steel is processed mostly, plus high-tensile and stainless steels, ranging from 8mm dia solid bar up to 50mm dia tube, and wall thickness is up to 3mm. More than 90% of tube is pre-processed with features and identification marks in a BLM LT5 tube laser cutting machine, also built in Italy, which was supplied in 2015 by the group subsidiary in Ampthill. This was another process that was formerly sub-contracted out, so control over production became tighter and costs were lowered.

Likewise, control over flat sheet metal parts supply to the fabrication and assembly department has been improved with the installation of the 6kW BLM LS7 fibre-laser cutting centre. Savings in sub-contract costs are predicted to amortise the investment quickly.

Pictured right: the flat-bed LS7 cutting a nested sheet of components

Pictured right: the flat-bed LS7 cutting a nested sheet of componentsMr Thorpe appreciates the modern features of the machine, including automatic sheet position sensing and alignment with the programmed path; active nozzle centring to maintain productivity, particularly during unattended operation; and active zoom, which changes the diameter of the laser beam to optimise cut quality and speed according to the gauge of sheet being processed.

Similar steel materials — mild, high-tensile and stainless — are laser profiled into components nested across 2.5 x 1.25m sheets. Tolerances of 50 microns are achieved, consistent with reliable fabrication of the components with the tubular elements.

Minimal time is wasted between processing one sheet and the next, as the outgoing movement of the table carrying the cut parts and skeleton, and the movement of the incoming table carrying a fresh sheet, are simultaneous. Table exchange is completed in under nine seconds, notably the fastest on the market. Supporting such high-speed motions is the machine’s steel base filled with a vibration-damping polymer that also provides strength and rigidity, enabling axis acceleration up to 2g and excellent trajectory accuracy during cutting.

Minimal material wastageAbout 95% of parts in the Ilkley facility are produced from sheet under 8mm thick using nitrogen as the service gas, enabling fast, clean cutting that delivers a high-quality edge with no oxidation, ideal for subsequent painting. Oxygen is used for thicker gauge materials, allowing more productive cutting compared to using an inert gas. Lantek software is employed for highly efficient nesting of parts, ensuring minimal material wastage.

Mr Thorpe continued: “The tube-manipulation machines and the laser cutter from BLM are top-quality machines, but by far the most important aspect for Olicana when choosing machine tool suppliers is the level of service we receive, because that is the only way we can guarantee continuity of production. It is crucial to our competitiveness.

Pictured left: the diameter of the laser beam may be automatically adjusted to optimise the quality of the cut edge according to the type of material being processed and its thickness

Pictured left: the diameter of the laser beam may be automatically adjusted to optimise the quality of the cut edge according to the type of material being processed and its thickness“It was clear from the purchase of our first machine from this manufacturer — the second-hand E-TURN 52 — that a high level of back-up was going to be forthcoming from Ampthill, even though they did not sell the machine to us. Engineers in the Italian factory were also willing to help if necessary and we even set up a WhatsApp group to aid communication. Overall we have been more than satisfied and it made continued purchases of tube benders and the flat-bed laser from the same supplier an obvious choice.”

He added that the quality of the after-sales support was evident even before the machines were operational. Both the latest tube bender and the laser profiler were installed and commissioned in one week and were in full production by the next, a feat he described as ‘impressive’. Similarly, training of Olicana staff on-site and in Italy was comprehensive and co-ordinated in a timely manner with the installation of the machines.