Dudley-based Dromafied Engineering Ltd, a leading precision sub-contract specialist, realised immediate benefits from acquiring a new DN Solutions’ Fourth Generation DNM 4500 vertical machining centre (VMC) from

www.millscnc.co.uk Mills CNC’s ever-popular and recently revamped ‘SMART Options’ machine tool rental scheme.

In addition to increasing the sub-contractor‘s in-house milling capacity and capabilities, the machine’s arrival in June 2025 proved to be perfect timing, when one of the company’s older machining centres suffered a spindle breakdown that caused it to be out of action for a short period.

Dromafield Engineering, which has two machine shops, made the decision to invest in a new DNM 4500 from Mill CNC, he exclusive distributor of DN Solutions’ and Zayer machine tools in the UK and Ireland, in the spring of 2025. The idea was to help take pressure off one of the company’s older machining centres which, owing to an increased demand from customers requiring high-quality milled parts, was in danger of becoming a production bottleneck which, and if not addressed would begin to have an adverse effect on turnround times.

Ben Nightingale, office manager and work scheduling co-ordinator at Dromafield Engineering, said: “One of our older machining centres, a box guideway Mynx 540 heavy-duty machining centre, equipped with full fourth-axis capabilities and acquired new from Mills CNC in 2005, was struggling to cope by itself with the increased volume of work coming its way.

“We did have another machining centre available within the machine shop, a DNM 500 acquired from Mills back in 2013, but this was effectively ‘ring-fenced’ with its capacity almost entirely dedicated to machining high-accuracy aluminium aircraft inspection equipment. It was clear that we needed additional milling capacity and that we needed it fast, and this led to us contacting Mills CNC to discuss acquiring a new machine.”

SMART Options rental schemeAs part of the new machine tool decision-making process, representatives from Dromafield Engineering visited Mills CNC’s Technology Campus in Leamington. It was here where they were first introduced to DN Solutions’ DNM Fourth-Generation series of three-axis VMCs and when Mills CNC’s SMART Options rental scheme was explained and explored in more detail.

Will Smith, CNC machine tool programmer and setter operator at Dromafield Engineering, reflected: “We were originally looking at acquiring another Mynx machine but sales and applications staff at Mills CNC, took time to present a number of different-size DNM machines they had in stock, and that were available for immediate delivery.

“Owing to our machine shop floorspace limitations, and the nature of our work, which can involve heavy duty roughing with high metal material removal rates (MMR), and the machining of a range of different materials, we knew we needed a flexible, compact and high-performance machine, and the DNM 4500, rather than the smaller and less powerful, DNM 4000, or the larger footprint, DNM 5700, seemed to fit the bill.”

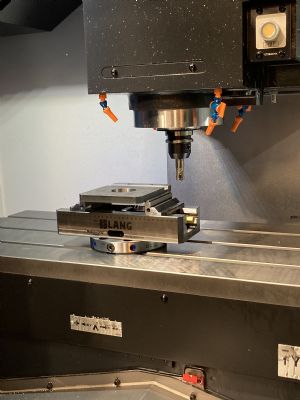

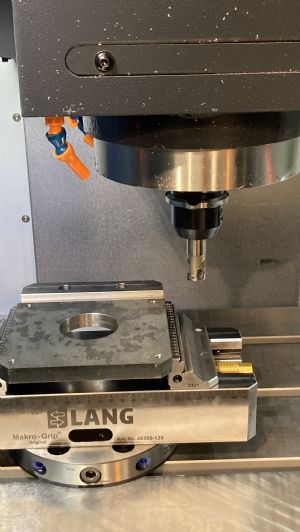

The Fanuc 0iMP controlled DNM 4500, with its rigid design and build, a 30-tool position automatic tool changer (ATC), a directly-coupled 18.5kW 12,000rev/min 117.9N-m high-torque spindle with 20bar through-spindle coolant capability, and a 1,000 x 450mm worktable with 600kg maximum table load, was demonstrated performing a number of heavy-duty, high-accuracy U-drilling operations on a solid steel billet.

Sam Nightingale, Dromafield Engineering’s CNC programmer and setter operator, explained: “We were impressed with the DNM 4500’s fast processing speeds and high-precision cutting capabilities, and could see that, by also investing in zero-point clamping systems, we could significantly reduce set-up and part cycle times and successfully address the backlog of milling work that had built up.”

Although the DNM 4500 has linear guideways, as opposed to the box guideway construction of the Mynx 540, Dromafield Engineering could see that by manipulating programs and altering machining parameters, such as cutting speeds, feed rates and depths of cut etc, the DNM 4500 would be able to process a high percentage of parts currently being machined on the Mynx 540.

Flexible optionsIt was during the discussions that Mills’ sales staff explained the SMART Options rental scheme which allows component manufacturers and toolmakers to rent, as opposed to purchasing outright, a new DN Solutions’ machine tool for an initial 12-month period with a number of flexible options at the end of the one-year.

These options include: returning the machine to Mills CNC; purchasing the machine with 100% of the rental payments already made refunded against the original price of the machine; extending the rental scheme for another 12 months. With no deposit required and with free delivery, installation and training included, SMART Options is a popular and proven way for manufacturers to cost effectively) increase their machining capacity and capabilities.

Ben Nightingale said: “SMART Options is a simple and straightforward rental scheme with no hidden extras or upfront costs to worry about. Once the details were explained, we made the decision to acquire the new DNM 4500 via this route.”

Although the DNM 4500 was essentially acquired to take pressure off the company’s Mynx 540, it was only three weeks after the machine’s installation, that the investment decision really came into its own, following a spindle issue that caused the Mynx 540 to be out of action for a short period of time.

Sam Nightingale explained: “Having the DNM 4500 in place enabled us to transfer some of the work over to the new machine. The investment really did get us out of, what could have been, a difficult situation.”

Parts machined on the new DNM 4500 are processed in small-to-medium batches, typically 20 to 500-off), and include components made from a variety of materials, including S355 steel, high-strength carbon steels, aluminium alloys, brass and phosphor bronze, for customers in the aerospace, automotive and crane and lifting gear industries.

Specific crane and lifting gear parts processed on the DNM 4500, to date, have included different-sized hook block components such as side plates, centre plates, pins, bolts, housings etc., and are machined to tight tolerances with +/-0.025mm being typical across whole parts or selected features.

Part cycle times, for smaller side plates that are machined from solid, are currently 6min. The company is hoping to get this down to 4min 30sec per part, or better, once the new zero-point clamping systems are in place. Dromafield Engineering, established in 2008, is no stranger to Mills CNC and from 2005 to 2013, the Dromafield Group invested in an impressive eight Doosan machines.

Fanuc-controlled machinesIn addition to the previously mentioned Mynx 540 machining centre supplied in 2005, Dromafield Engineering’s other machines acquired from Mills CNC are all Fanuc-controlled and include a Puma 400LB large-capacity lathe acquired in 2009, four Lynx 220 lathes acquired between 2010-2011, and a three-axis DNM 500 VMC acquired in 2013.

Will Smith said: “We have a good, long-standing relationship with Mills CNC that go back over 20 years. When we were looking to increase and improve our milling capacity it was natural that Mills CNC was our first port of call.”

Although Dromafield Engineering has had its new DNM 4500 for approximately six months, the arrival of new Lang Zero Point clamping systems last month will enable the company to significantly improve productivity and process efficiencies by further reducing set-up times and increasing machine uptime via quick and repeatable positioning of fixtures and workpieces.

Dromafield Engineering is a private, family-owned business headed up by co-owners and directors, Paul Smith and Glyn Nightingale, with day-to-day operations managed by the directors’ sons, Will Smith and Ben and Sam Nightingale. The three sons have effectively become, and operate as, Dromafield Engineering’s new, de-facto management team and, with an average age of just 28 years, the company has an effective succession plan already in place that assures its future for years to come.

The company was originally established in 1974 by Will Smith’s grandfather and traded as Dromafield Ltd until 2008 when the company was incorporated as Dromafield Engineering Ltd, with Paul Smith and Glyn Nightingale taking over the reins. The company is successful and profitable and has developed long-term relationships with a number of customers, many of whom have placed work with Dromafield Engineering for over 20-years.

Will Smith concluded: “We provide a first-class, high-quality machining service, including reverse engineering, to customers. The machine tools at our disposal ensure that we deliver ‘right first time’ milled and turned components, on-time and in-budget.”