Established in the 1980s, Gosport-based

www.mpe.ltd Mathison Engineering Ltd has evolved from a one-man operation to become a precision-engineering business serving the marine, aviation, and food industries. Managing director Steve Mathison, who took over from his father, says it was some 20 years ago that the company began working with the tooling company

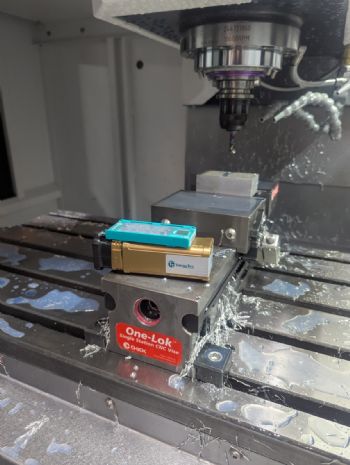

TaeguTec UK Ltd, Leeds and its senior technical sales engineer Iain Lacayo — a relationship that has helped Mr Mathison gain maximum benefit from the new SYIL machining centres he recently installed.

Commenting on the installation of these machines, Mr Mathison said the company had been faced with the frustrating paradox of high-performance TaeguTec cutting tools and machinery that could not exploit their full potential.

“Some of our machines were just too old and were struggling to keep up with the recommended tooling. For example, where TaeguTec tooling could run at speeds well beyond 20,000rev/min, our machines were limited to about 10,000ev/min, which meant the potential of TaeguTec’s tooling had never been realised. Despite these constraints, TaeguTec remained our primary supplier. However, in March 2025 we installed an SYIL X5 machining centre with a 20,000rev/min spindle, and for the first time our machinery and TaeguTec tooling were properly aligned.

“For milling operations, we depend heavily on TaeguTec’s indexable solutions. For example, the WinMill system’s 8mm two-flute indexable end mill with CVKT inserts has become indispensable for small slots and detailed work, effectively replacing solid-carbide tooling with a more economical solution, while the Chase4Mill system, with its 90deg, four-edged inserts, handles everything from rough milling to precision shoulder work. Furthermore, the ChaseMold system with RYMX inserts excels at the stainless-steel milling that is common in our marine component work.

“What distinguishes TaeguTec for us is the consultative approach, with Mr Lacayo analysing every new application to make sure we use the tooling that is most effective regarding cost and performance. Indeed, he saves us a lot of money with his knowledge of the TaeguTec range. Furthermore, with the SYIL X5 running our TaeguTec tools at their designed parameters, they are definitely lasting longer. We also consulted Mr Lacayo when we recently purchased a SYIL X11 machining centre with a five-axis rotary table.”

Mr Lacayo concluded: “The X11 is equipped with 20-bar coolant pressure, which allows Mathison to use TaeguTec’s Typhoon high-speed machining system. Operating at 35,000rev/min with high-pressure coolant delivery, the Typhoon system will enable even more aggressive cutting parameters and take the company into the area where small cutters are in the ideal window of where they should be.”