Aberdeenshire-based

STATS Group (STATS), a market-leading global supplier of pressurised pipeline isolation, hot tapping and plugging products and services to the global energy industry, has recently invested in two new DN Solutions advanced machine tools from

Mills CNC, the exclusive distributor of DN Solutions and Zayer machine tools in the UK and Ireland.

The two new machines — a compact high-performance multi-tasking lathe and a large-capacity simultaneous five-axis machining centre — both installed at STATS’ Kintore machine shop facility in September 2025, have significantly upgraded the company’s in-house machining capacity and capabilities and have already made their mark — improving process and operational efficiencies, and increasing overall productivity levels in what is a period of significant growth for the company.

The acquisitions are already enabling STATS to not only reduce its reliance on external third-party machining suppliers, but is also helping the company eliminate production bottlenecks and pinch-points, increase process and operational efficiencies, reduce costs and improve productivity.

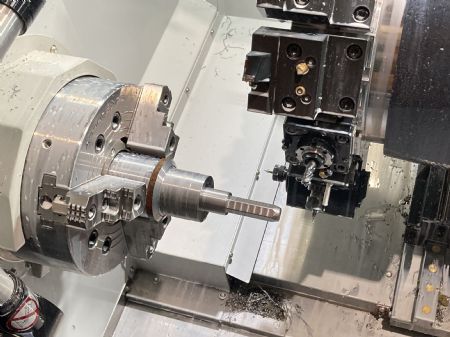

The 10in chuck Lynx 2600LY is a fast, accurate and flexible compact machine, and one of Mills CNC’s best-selling and ever-popular multi-tasking lathes. The machine supplied to STATS was equipped with an 18.5kW 3,500rev/min spindle, a 12-station turret, 6,000rev/min driven tooling capabilities, a +/-52.5mm Y axis and an automatic tailstock, a bar puller, and a swarf conveyor and bin. The VCF 850LSR II is a high-performance, large-capacity simultaneous five-axis machining centre that features roller-type LM guideways, a 12,000rev/min B-axis spindle, an integrated built-in 800mm rotary table, a 60-tool automatic tool changer (ATC), and a centre partition.

Growing global footprintEstablished in 1998, STATS Group has a growing global footprint with operational facilities, including manufacturing, workshop and engineering capabilities in the USA, Canada, Australia, UAE, Qatar, Saudi Arabia and Malaysia.

Pictured left: the 10in chuck Lynx 2600LY on the shopfloor at STATS

Pictured left: the 10in chuck Lynx 2600LY on the shopfloor at STATSThe company, acquired by Japanese conglomerate Mitsui & Co in 2023, is a major player in the global energy sector designing, manufacturing and supplying a range of innovative, patented pipeline isolation, intervention and repair products and services. STATS’ best-in-class engineering and customer-focused approach has earned the company a large and expanding customer base of national and international oil, gas, and petrochemical companies, as well as pipeline operators.

STATS excels in the servicing of large-diameter, high-pressure pipelines and with demand

for extending the life of aging infrastructure through planned and preventive maintenance set to increase, the company is well positioned for growth. Demand for STATS’ proven, patented solutions including the BISEP®, fail-safe double-block and bleed line stopping tool and the Tecno Plug, a piggable inline isolation tool, is expected to rise significantly.

STATS’ extensive product range, that includes pipework and pipeline isolation and intervention tools, hot tapping machines, mechanical clamps and connectors, are all designed and manufactured in-house, with the company’s machine shop playing a pivotal role machining the many different high-quality (metal) components that go into each and every product.

Facing increasing demand and the need to support customers’ maintenance schedules under tight deadlines, STATS undertook a comprehensive strategic audit of its in-house machine shop. Driven by its commitment to continuous improvement, the company reviewed operations to pinpoint current and emerging challenges related to quality, lead-time delivery, and cost efficiency.

Advanced technologiesKrzysztof Wozniak, STATS Group’s manufacturing manager, said: “Because we manufacture all of our products in-house, and because we operate to very tight deadlines, it is vitally important that we have access to advanced technologies and efficient processes that improve our machining performance, reduce lead times and make us more competitive.

“Although we have a range of CNC and manual tools at our disposal, some of them are ‘legacy’ machines whose processing speeds, accuracies and flexibility have been superseded by more advanced machine tool models now available on the market.”

Due to substantial business growth and a rapidly expanding order book, STATS recognised that its existing machining capacity was no longer sufficient to meet demand. Legacy equipment was also underperforming, creating bottlenecks and inefficiencies that required urgent attention.

Pictured right: Driven tooling on the 10in chuck Lynx 2600LY

Pictured right: Driven tooling on the 10in chuck Lynx 2600LYWithout investment in ‘state of the art’ machinery, it was decided that a significant proportion of work would need to be outsourced to third-party machining suppliers, increasing costs and lead times and ultimately putting critical turnround times at risk. An audit also highlighted inefficiencies experienced by STATS’ previous ‘mix and match’ approach to acquiring machine tools with different CNC control systems, and the difficulties this presented in being able to transfer programs, seamlessly, between machines.

STATS made the decision to take pressure off its small turned part processing operation by investing in a new multi-tasking lathe. Michael Forbes, STATS Group’s operations manager said: “We had previously acquired a used two-axis Fanuc-controlled Lynx lathe a couple of years ago and were impressed with its cutting capabilities, fast processing speeds, high precision and reliability.

“The machine had been in constant use since being installed but, owing to the increase in demand for small, high-quality turned components, could not keep up with the volume of work now coming its way. Only having one small lathe at our disposal had created a serious bottleneck that could only be alleviated by sub-contracting the work out or by strengthening our in-house machining capacity by investing in a new, high-performance machine — we opted for the latter.”

However, rather than invest in another two-axis lathe to help clear the backlog and attempt to put its small turned part operation back on an even keel, the company made the decision to acquire a new Fanuc-controlled multi-tasking machine with integrated Y axis and driven tooling capabilities instead.

Full mill-drill capabilitiesMr Forbes explained: “Having access to a lathe with full mill-drill capabilities, we believed, would not only enable us to process small turned parts quickly and more efficiently in one set up, and eliminate the need to transfer parts to a milling machine for completion, but would also free-up time on the small milling machine too — a win-win situation.”

The company’s positive experience with its first Lynx lathe led STATS to approach Mills CNC to discuss its new turning requirements, and it was through these discussions where the specification of the Lynx 2600LY and its availability were outlined to STATS’ representatives.

As previously mentioned, STATS had a number of different machine tools at its disposal, one of these being a relatively large-bed milling machine that was proving to be unreliable and prone to downtime. Not having access to a large and reliable milling machine had resulted in STATS sub-contracting this work out which was particularly frustrating as most of it was neither complex or time-consuming.

Mr Wozniak said: “Sub-contracting the work out was expensive and meant that we were no longer in control of our own production schedules. It was clear that we needed to resolve the situation quickly and that investing in a new large-capacity mill would be the right move.”

With so many different potential machine tools being available, STATS, prior to approaching the market, did its homework and, following internal discussions, created a new machine checklist identifying ‘must have’ technologies, capabilities and features to help narrow down its choice.

Pictured left: the integrated built-in 800mm rotary table on the VCF 850LSR II

Pictured left: the integrated built-in 800mm rotary table on the VCF 850LSR IIMr Wozniak added: “We were trying to future-proof this investment as much as possible so, in addition to the machine having a large worktable and long X-axis stroke for processing long and/or multiple smaller workpieces in one set up, we also needed the new machine to have full simultaneous five-axis capabilities, a powerful, high-torque spindle, fast rapids, an integrated rotary table, an automatic tool changer (ATC), the latest Fanuc control, and in-process tool and workpiece measurement.”

Armed with its requirements and needing the machine to be available quickly, STATS went to market asking for quotes from a refined number of machine tools suppliers. Mr Forbes said: “It was the VCF 850LSR II’s technical specification that put Mills CNC in the box seat. With Mills CNC having the machine readily available in stock, ready for immediate delivery, effectively helped seal the deal.”

Since being installed, and following operator training, both machines have been put to work machining a range of components that are typically made from carbon steel, stainless, duplex, aluminium and some exotics including Inconels.

Although the machines are not being pushed to their limits in terms of positional and repeatable accuracies, it is their fast-processing speeds, inherent flexibility and reliability that enables them to machine a wide range of components, in varying batch sizes, from different materials in double-quick time, where they have been particularly successful.

Mr Forbes concluded: “Our investment in two new DN Solutions’ machines have had a dramatic impact on our productivity and process efficiencies. The backlog of work has already been significantly reduced and, because we are no longer having to sub-contract out work to external suppliers in the volumes previously required, we are now back in control of our production processes and better able to meet our customers’ delivery schedules and deadlines.”