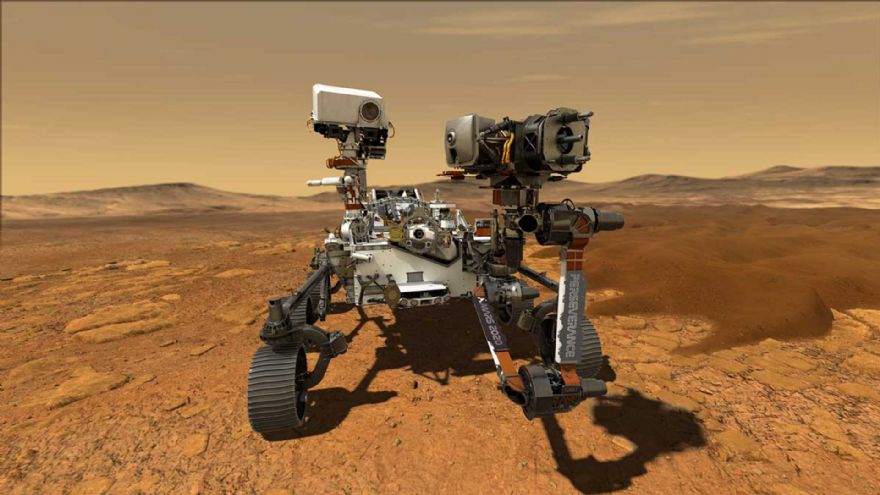

The Mars2020 mission successfully blasted off from Cape Canaveral on 30 July, taking with it the Perseverance rover on a seven and a half month journey, to look for signs of life on the surface of the red planet.

The aim is to examine Martian rocks and soils in greater detail than ever to determine the geologic processes that formed them; study the Martian atmosphere; and determine the distribution and circulation of water and carbon dioxide, whether frozen, liquid, or gaseous. It is foreseen that the rover will operate on the Mars surface for 1.5 Martian years (1,030 Earth days) or more. The rover will land in an area called the Jezero Crater which has a high potential for finding signs of past microbial life.

Apart from studying the Martian biological and geological environment, the vehicle will also retrieve and store samples on the planet's surface that will be collected later by the European vehicle called Mars Sample Fetch Rover whic is being developed by Airbus and scheduled for launch by 2026.

Product of a bilateral agreement between Spain and the USA, Airbus in Spain had the chance to contribute to the Mars 2020 mission with two important elements on board Perseverance, the High Gain Antenna System and the MEDA meteorological station.

The Madrid-Barajas site of Airbus, built the Mars2020 High Gain Antenna System (HGAS) for NASA’s Jet Propulsion Laboratory (JPL) which included an X-band steerable antenna for transmission and reception that will provide high data rate direct-to-Earth communications to and from the Perseverance rover.

This system is a recurrent model (except obsolescence) from Curiosity’s High Gain Antenna System which is still operational after almost four Martian years (2,748 Earth days), the plan for Curiosity was to operate for one Martian year (687 Earth days).

The HGA system, on board the Perseverance rover, consists of two sub-assemblies, the high gain antenna and the Gimbal mechanism. Airbus was responsible for the complete system as well as the thermo-mechanical and Radio Frequency design, manufacturing, integration and testing of the planar array antenna HGA. As sub-contractor, SENER (Getxo, Spain) supplied the pointing mechanism of the antenna or HGAG.

HGA is an X-band with circular polarisation planar array patch antenna for reception and transmission. It is based on the micro-strip technology developed in-house and it is protected against dust, maintaining thus, the ideal thermal and clean conditions.

The diameter of the antenna is around 30cm and the weight of the complete system is 8kg of which, only 1.4kg belongs to the HGA antenna. Its main mission is to send to Earth, without the need for intermediate links (orbiters), the scientific data generated by the different instruments, and information on the rover's own health condition. In addition, it can also receive daily instructions from the control centre station for the rover to carry out its mission. Being steerable, it can send a "beam" of information pointing directly at the Earth and without the need for the vehicle to move, which contributes energy savings.

The atmospheric conditions of Mars require the antennas to be subjected to a stringent acceptance test campaign in order to ensure the reliability and compatibility of the specimen with this harsh environment. The extreme thermal excursions on Mars require to validate the antenna system to temperatures varying from -135ºC to +90ºC.

Specific parts of the antenna design were exposed to a thermal fatigue test that lasted approximately 9 months.

Ana Olea, programme manager at Airbus in Madrid-Barajas, said: “The relationship with JPL has been exceptional, as it was in the past with Curiosity. I would say it was a fluid relationship at all times, one of trust and with the common goal of building a High Gain Antenna System to meet the design requirements on schedule.

Economic activity falls but at a slower paceEach difficulty encountered was solved with a team spirit that concluded with the delivery of the system on time, with great satisfaction from the client, JPL.”

Perseverance also carries on board a weather station that has been developed in Spain. The scientific mission and the instrument concept have been conceived at the Astrobiology Centre (at the National Institute of Aerospace Technology, CSIC-INTA) while the design and integration have been carried out by the site of Tres Cantos of Airbus near Madrid. This work has been financed under ESA and INTA/CAB contracts. It is not the first time that the collaboration between Public Institutions and Industry undertakes such a feat.

The MEDA instrument (Mars Environmental Dynamics Analyser) will measure numerous environmental parameters throughout the nominal mission of 1005 Martian days, equivalent to 1030 Earth days.

MEDA has sensors distributed in the Rover to measure parameters such as wind direction and speed, relative humidity, atmospheric pressure, solar radiation, properties of suspended dust and also soil and air temperatures.

It also has a camera to take images of the Martian sky, including its clouds.

Airbus contributed to the instrument the complete development of the Instrument Control Unit and flight software; the development of electronics, integration and testing of two wind sensors; the complete development of the Iinfra-red sensor; systems engineering, quality control, and instrument integration.

MEDA will be the third Martian environmental station led by Spain, after REMS (Rover Environmental Monitoring Station), which arrived on Mars in 2012 aboard the Curiosity rover, and TWINS (Temperature and Wind for InSight), on the surface of Mars since the end of 2018 on the InSight mission, all from NASA/JPL.

Thanks to these instruments, scientists have access to highly relevant information on the meteorology of Mars, information that will be even more accurate with MEDA. Understanding the meteorology, its dynamics and its cycles are key to understanding many other facets of the red planet.

Tirso Velasco, MEDA Project Manager at Airbus in Tres Cantos, said, “Collaborating with NASA/JPL on three instruments - REMS, TWINS, and MEDA - over nearly 15 years has been extraordinary. Not only has it allowed us to evolve critical technologies to enhance the ability to do science on Mars, but we have built a long-term relationship with NASA that highlights Airbus' ability to develop technology at the forefront of planetary exploration.”

Mars Sample Return is a joint NASA and ESA campaign to return samples from the Red Planet to Earth. NASA’s Mars 2020 mission with the Perseverance rover will collect Martian soil and rock samples and leave them on the surface in small metal tubes.

In 2026 NASA will launch ESA’s Sample Fetch Rover to Mars to collect these tubes. Landing in 2028, this rover, being developed by Airbus, will travel an average of 200m per day over a period of six months to find and pick up the samples.

It will collect up to 36 tubes, carry them back to the lander and place them in a Mars Ascent Vehicle which will launch them into orbit around Mars. Another spacecraft developed by ESA (with a NASA payload), the Earth Return Orbiter (ERO), will detect, rendezvous and capture the samples from the Martian orbit and return them to Earth.