Open Mind Technologies AG

Open Mind Technologies AG, which has a UK subsidiary in Bicester, recently released the latest version (2020.2) of its HyperMill CAD/CAM suite.

This ‘drives forward’ automation and the integration of additive manufacturing; it also implements functions designed to further simplify everyday machining tasks.

These include new strategies for the machining of ‘cutting edges’, upgrades for mill/turning, parametric design in HyperCAD-S and the ‘HyperMill Automation Centre Advanced’.

Plunge-milling cycles have been added to the 3-D and five-axis strategies for the machining of ‘cutting edges’, with a plunge-milling process that reduces vibration for surface edges with steep walls, thereby improving the surface finish. Moreover, any rest material machining using a smaller tool is easily calculated automatically from the previous job.

With the latest version of HyperMill, the ‘Mirror Path’ function enables simple mirroring of the previously calculated tool-paths. Users benefit from shorter calculation time and improved process reliability. The user-friendliness of the software has also been further improved.

For a faster search in the tool database, the filter properties are now integrated into the top level of the user interface and are pre-loaded with the material from the job list and the ‘spindle holder from the machine properties’. Feature management has also been improved to save time during programming.

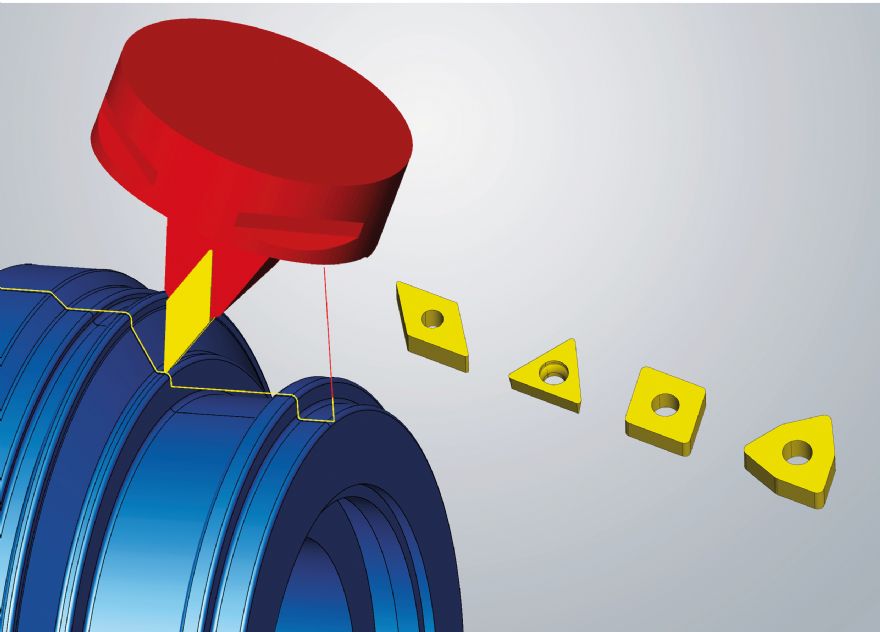

With regard to three-axis simultaneous mill/turning, round inserts, as well as rhombic, T, and W inserts, can now be used; there is also now a function to control the approach and retract movements by applying user-defined curves for all turning strategies — and all movements are still collision checked, despite the manual operations.

The ‘HyperMill Automation Centre’ now offers an optional advanced version that offers additional functions and templates; the latter allow users to define and standardise complex processes independent of the specific geometry from any one CAD model.

Meanwhile, HyperCAD-S allows components to be modelled directly parametrically for ‘fast production-related designs’. For example, a user can design a fixture plate parametrically and change dimensions to define different variants to the base model very quickly.

Moreover, a user can use a static solid model in parametric mode and add parametric features to it for a hybrid approach — and parametric geometry data used in HyperMill is associatively linked, with changes updated automatically.

HyperCAD-S also offers new interfaces for CATIA V6 3DXML and Rhino 3dm. PMI (non-geometric) data is now also available for CATIA, Creo, JT, NX, SolidWorks and STEP files.