Southampton-based

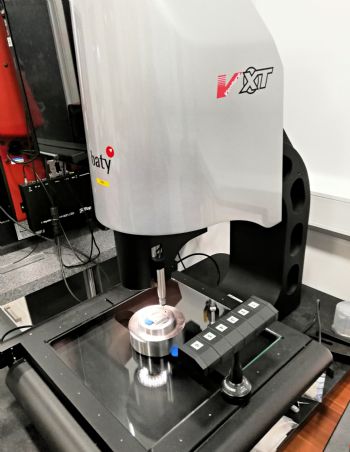

Williams Aerospace Engineering (WAE) has invested in a Baty Venture XT CNC Vision System, supplied by Camberley-based

Bowers Group, to measure critical precision machined components manufactured at its facility in Northam.

Specialising in five-axis CNC turn/mill centres, four-axis milling, internal and external gear and spline cutting, internal and external grinding, match grinding and honing with sizes from 0.062-6in diameter, the company works to tolerances of .002mm with 1µin surface finish.

Components machined by WAE are used in some of the most extreme environments, including aerospace, defence, nuclear, medical, Formula One/performance sports car and commercial markets.

In order to meet the demands of specific customers, the company manufactures anything from one-off components to large batches.

One of the biggest challenges facing WAE was the sheer amount of time it took to measure components and collate all the data for its customers.

For example, for a customer with particularly high-measurement requirements, it would take the quality department one to two days to measure the positions of two holes on a batch of 100 cover plates, in addition to having to input data to an Excel spreadsheet to customer requirements.

Since the investment in the Baty Venture XT CNC Vision System, this measurement process can now be completed in just 2hr, which is a massive 96% increase in measurement efficiency.

The inspection team at WAE are able to load the fixture onto the machine, insert a part, recall the programme and teach the datum position, completing the batch of the same 100 parts within this much shorter time-frame.

Ensuring product qualityDavid Fripp, WAE managing director, said: “The Baty Venture XT helps to ensure our product quality by giving us a more consistent and repeatable measurement method. Once a program is written, the Venture is far more accurate than our old manual CMM, which is reliant on the points taken by the operator moving the probe by hand, rather than the CNC control on the Baty system.

“It is very easy to use and the camera resolution is far more accurate than a standard projector using surface illumination.”

WAE uses the vision system for measuring lengths, radii, rads and angles. The measurements are either taken directly from the part loaded on the machine, or if it is an internal feature, it is reproduced using a rubber compound. The mould is then sectioned and measured on the projector as with an external profile.

He added: “The Venture gives us the flexibility to measure countersink diameters while measuring hole positions on the same part. Due to the camera’s focal length, it is also possible to focus on counterbores or countersinks that are located within a bore and take measurements, rather than take a mould and use a standard projector.

“We are very much looking forward to seeing how much more we can achieve with this piece of equipment in the future.”

The Baty Venture XT is used most days either to perform first off, in process, or final inspections on parts which are being manufactured at the facility.

Two members of the inspection team at WAE currently use the Baty Venture, but as programs and fixtures become available to use in the future, other personnel will be able to recall programs and perform their own in-process inspections. This will then allow the inspectors to concentrate on other areas.

Incorporated as City Tool & Gauge in 1935, which became N. Williams & Co (Southampton) Ltd in the early 1960s, and finally renamed as Williams & Co (Southampton) Ltd, Williams has been at the cutting edge of engineering ever since.

The business also offers full inspection capabilities to check surface profile, such as roundness, cylindricity, and concentricity, which are fully calibrated to ACAS standards.