Together with

Jungheinrich, Liebherr-Werke Ehingen GmbH is building a new central spare parts warehouse at its German headquarters in Ehingen, Baden-Württemberg.

As a global leading manufacturer of mobile cranes, Liebherr intends to handle its world-wide distribution of spare parts from June 2023 onwards.

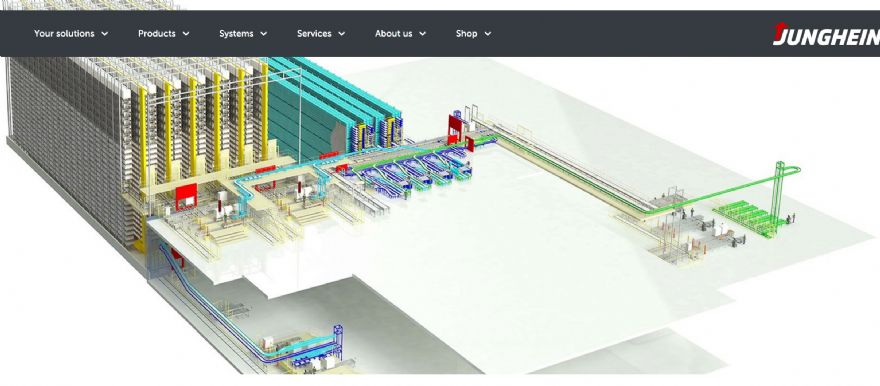

At the heart of the logistics solution, which Jungheinrich is delivering as single provider, is an automated six-aisle high-bay warehouse (HBW) for pallets in a rack-supported structure with 18,000 rack storage locations – including in the roof and wall panelling.

At 80m long x 75m wide x 30m high, its dimensions are impressive. In addition, it has a two-aisle, three-fold deep automated mini-load shuttle warehouse (MSW) with rack storage locations for a total of 40,000 containers.

These two warehouse types will ensure the maximum usage of space for Liebherr’s distribution of spare parts while, at the same time, improving handling performance. By putting the warehouse into operation, the company wants to set new standards in regard to quality, functionality and safety, and ensure the consistently high availability of its machinery around the world.

The product range of the Liebherr plant in Ehingen includes ‘state of the art’ telescopic and lattice boom cranes of different sizes, both mobile and on continuous tracks; the scope spans from all-terrain mobiles cranes of 35 tonnes to gigantic crawler cranes with load capacities of 3,000 tonnes.

In addition to the HBW and MSW racking systems and the latest conveyor systems for containers and pallets – including control units and visualisation – the system solution, which Jungheinrich developed as a general contractor for the Liebherr plant, also includes six stacker cranes for pallets from the Jungheinrich subsidiary MIAS.

Each of these is fitted with dual-load handling equipment to ensure the fast pace of the stacking and picking of Liebherr spare parts are completely automated and run smoothly 24/7.

In communication with Liebherr’s ERP system, Jungheinrich’s Warehouse Management System (WMS) will take over the control of not only the automated facility but of all other processes of the surrounding manual areas of the warehouse. All functions and solutions are tailored precisely according to the requirements of Liebherr.

This includes the pre-commissioning of containers in multi-order mode with pick-by/put-to-light and the subsequent consolidation as part of the order picking of pallets. Additional pick-and-pack order picking in shipping boxes is also carried out.

This happens at the same place of the container pre-commissioning as well as at a further workplace where orders of both pallets and containers in shipping boxes are picked.

Jungheinrich project manager Robert Schad said: “The logistics solution that we have developed for Liebherr paricularly stands out due to its high flexibility. — it can be expanded without difficulty and is therefore already equipped for the future growth of spare parts operations.”