Belgium-based

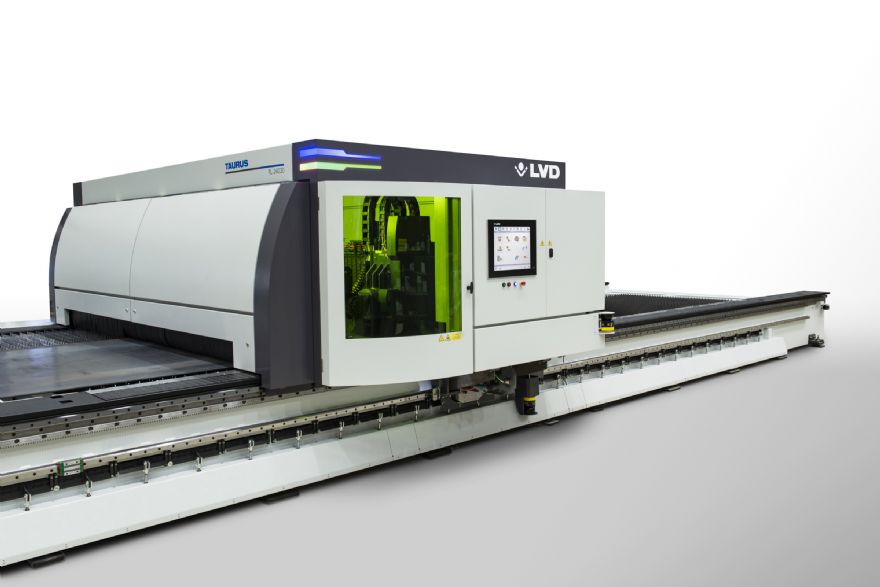

LVD, a leading manufacturer of sheet metalworking equipment, has launched Taurus FL, a new large-format gantry style fibre laser cutting machine designed for extra-large sheet metal cutting.

Featuring a unique modular design, the machine size begins at a 12m bed length and can be expanded in increments of 2m to a maximum bed length of 40m to suit user needs. The large format allows a wide range of parts to be cut and efficiently nested, increasing productivity and optimising material usage.

Taurus FL delivers the flexibility to process extra-large sheets or multiple sheets of varying batch sizes, shapes and material types and can accommodate workpieces up to 3.3m wide x 30mm thick.

Large parts can also be processed without repositioning while multiple smaller workpieces can be positioned on the cutting table and processed in continuous fashion, without interruption. Parts can be cut on one section of the table, while loaded/off-loaded on another, keeping downtime to an absolute minimum.

Taurus FL is designed for easy access — only the gantry features an enclosure, not the complete machine. The mechanical design and drive system ensure high machine dynamics in large-format cutting. The operator has use of two touch panels for convenient access to the control at all times.

A hand-held control unit enables the operator to safely move all axes in manual mode for machine setup or to load the nozzle changer. A camera located inside the cutting zone and a monitor on the operator console allow continuous monitoring of the cutting process. The cutting zone has a detachable front panel, providing access for maintenance. No special foundation is required for the machine.

High-quality bevel cutsTaurus FL also provides the option of bevelling cutting or 2.5D cutting up to 45deg. The fibre laser is an ideal tool for reliably producing high-quality bevel cuts in a large-format cutting platform. The bevel cutting option offers a fast and cost-effective way to prepare material for subsequent welding operations or to create geometrical shapes.

The bevel head uses two direct-drive motors which have no transmission components resulting in the highest possible accuracy and a fast responding system which ensures consistently precise bevel cutting. It can cut on a horizontal surface as well as cut shapes in pre-formed parts or cut under angle within the limits of the Z axis and +/- 45deg.

Morever, an optional automatic nozzle changer increases machine uptime and throughput. The unit has storage for 30 nozzles in a turret-style holder positioned close to the cutting head. The nozzle changer features an integrated camera that checks nozzle alignment, size and condition. It offers automatic calibration of the capacitive height sensing and nozzle cleaning after a preset number of piercings.

Optional CADMAN-L software includes automated functions to simplify programming and offers advanced nesting, collision avoidance, on-the-fly piercing and cutting, and process parameter tables to realise the full potential of Taurus FL. For bevel cutting, an optional plug-in is available for SolidWorks, Solid Edge and Inventor software packages.

Taurus FL is offered with either a six, eight or 10kW fibre laser source, which boasts an industry-leading wall-plug efficiency of more than 40%.