New laser structuring robot developed

Posted on 02 Dec 2020. Edited by: John Hunter. Read 2037 times.

ModuleWorks

ModuleWorks and the

Fraunhofer Institute for Production Technology (IPT) have developed a robot for cost-effective laser structuring of large surface areas.

Laser structuring is used to repeatedly mark or engrave complex 3D geometries. It has significant ecological and aesthetic advantages over conventional surface machining but is expensive when it comes to manufacturing large surface parts. Large surfaces must be divided into smaller areas which are then processed sequentially.

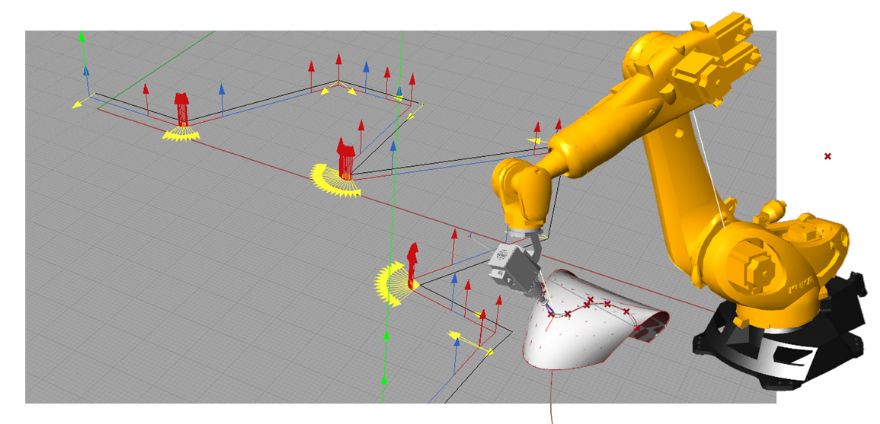

To avoid visible transitions between the areas, the laser needs to be frequently repositioned with a high degree of accuracy which requires complex and expensive plant technology. The new system developed by ModuleWorks and Fraunhofer IPT replaces the expensive positioning equipment with a cost-effective industrial robot.

The laser structuring module is mounted on the robot. Data from an inline camera is passed to the ModuleWorks toolpath calculation engine where intelligent algorithms modify the toolpath on-the-fly and drive the robot with the required degree of precision.

Used for the first time in laser structuring applications, the industrial robot reduces investment costs by up to 80% to make laser structuring a profitable production process for parts with large surface areas, such as automotive bumpers and dashboards.