As the world ramps up being able to distribute effective vaccines against Covid-19, a leading supplier to the pharmaceutical industry is manufacturing packaging components and delivery systems ready to support the vaccine’s availability.

West Pharmaceutical Services has 25 manufacturing sites around the world, including a plant in Cornwall where it manufactures tools for elastomeric packaging components.

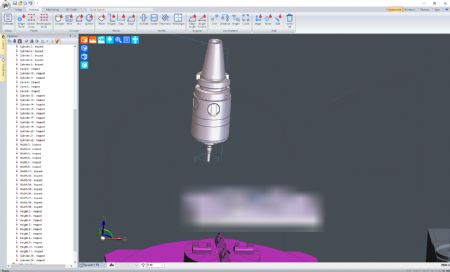

The company’s mould tools are produced on a range of 24 machines, comprising: Makino V80S five-axis VMCs; Haas VF, VM and Mini Mills; and Ingersoll V5 CNC machines — all programmed with

Edgecam software from Hexagon’s Manufacturing Intelligence division.

While mould tools are designed at another of West Pharmaceutical’s European plants, the CAD files for the tools are imported into Edgecam at the company’s Bodmin workshop.

Chris Tamblyn, the interim production manager, said: “Until recently, we used wire-frame 2-D CAD files; and while there is still some legacy work for old low-demand tools that need to be refurbished, all our new work is based on 3-D solid models.”

West Pharmaceutical’s mouId tools produce literally hundreds of millions of plastic and rubber products throughout their life cycle. Moreover, current demand is ‘solid’, from existing customers as well as new ones looking to develop Covid-19 solutions.

He continued: “There has been a recent upsurge in products required for the fight against Covid-19, including vials, stoppers, plugs and plungers.

“Customised routines play an important role in the traditional manufacture of our steel tools. We import the CAD data into Edgecam and work on all six faces with multiple set-ups. However, because our tooling is often very similar to something we’ve produced before, we have a number of repetitive operations, cycles and requirements.”

Mr Tamblyn added: “Over the years we have created a lot of routine files; so now, whenever we can, we use pre-constructed files that we have customised ourselves to populate our sequences. Once we have created a new routine it is stored in Edgecam and can populate a sequence extremely quickly, to work on multiple features. It is then outputted through Edgecam, and once the tool-path simulator has approved the program it is released to the machine network.”

A different process is adopted for graphite tooling, one that uses only solid model CAD data for full five-axis machining.

“Each electrode is uniquely designed for each tool; and because our electrodes are high cavitation types we don’t just make one feature on one electrode; one piece of graphite can hold up to 200 small, unique features.

“Our ability to do this was facilitated by Edgecam engineers customising our post processors, allowing us to create files very quickly and respond to changes.”