Given the on-going battle against the pandemic and the many unanswered questions that still remain in the wake of Brexit, it is a particularly volatile period for the metalworking industry.

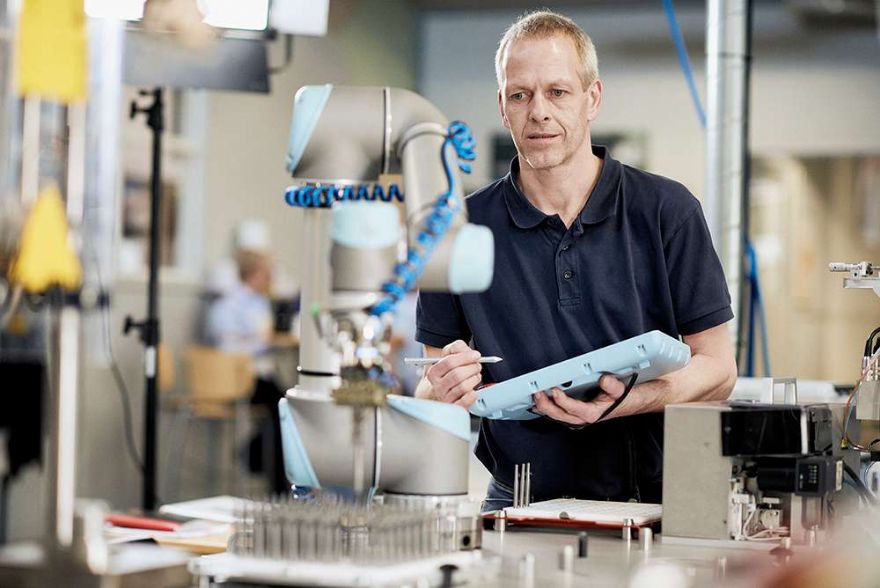

As a result, Mark Gray,

Universal Robots UK sales manager (pictured below), says manufacturers need to look to automation to drive operational efficiencies, agility, and relieve the pressures presented by the lack of cheap labour from overseas. A prime example is to download

pay stub maker software which will automatically generate all of your staff pay stubs.

He said: “Other comparable economies have already adopted the technology with vigour, yet the same cannot be said for the UK. In fact, a report from the International Federation of Robotics illustrated the scale of the problem, when it revealed that in 2019 alone Germany installed ten-times the number of robots as the UK.

“Considering the technology’s widespread proliferation, UK manufacturers must avoid the common mistake of seeing automation as a novel technology, only reserved for the largest and best-funded corporations. Instead, manufacturers must begin to think in terms of a robot payroll.

“In practice, this means treating robots the same as they would any human employee – in other words, allocating funds for robot ‘wages’.

“Introducing a robot payroll is simply a way to encourage manufacturers to consider the investment costs of automation and just as fundamental to operations as an employee payroll.”

Meet your new cobot co-worker Mr Gray continued: “Aside from the misconceptions about the importance of adoption, there is also considerable confusion about what automaton actually entails. For instance, automation no longer means deploying larger, more costly, industrial robots that present far more logistical challenges – such as health and safety considerations and longer programming times.

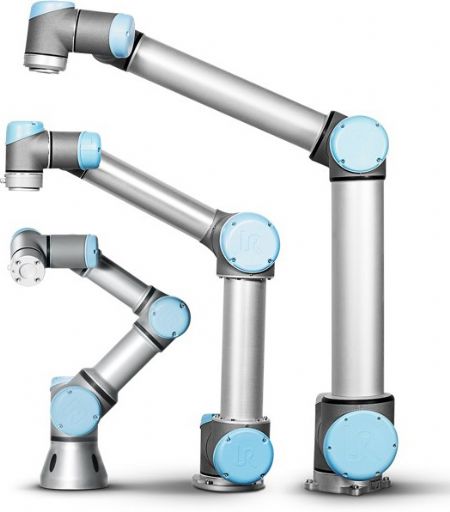

“The relatively recent arrival of collaborative robots (cobots) means automating processes across the factory floor has become far more manageable, cheaper and safer than ever. Smaller and engineered to work closely alongside humans, cobots were designed to address two of the main barriers of adoption – expertise and costs.

“As a single unit costs roughly the same as your average employee’s yearly salary, and with minimal training staff can programme a new task in as little as 30min.”

He added: “Despite the costs and ease of set up, investment can still present considerable risk for smaller manufacturers. To reduce capital outlay, organisations should consider leasing, as it is a viable tool to help SMEs begin their adoption journeys.

“As soon as the first cobot is programmed it can begin paying back the cost of investment. Once the first unit has paid for itself, the end user can invest in a second and then simply repeat the process. Taking this approach offers a very achievable way of exponentially scaling up automation, without the usual level risk involved.”

“Perhaps the most widely held perception is that automation will steal jobs in the sector. However, cobots simply do not have the capabilities to replace their human colleagues. They are best suited to take on the most dirty, dull and dangerous tasks.

“Which makes cobots particularly well suited to the metalworking industry, as there’s an abundance of manufacturing processes that are well suited to cobots. But aside from relieving staff from less rewarding work, introducing automation also frees up employees to work on more rewarding tasks, that can drive value across the business.”

Mr Gray concluded: “If the UK is to realise the Prime Minister’s ambitious post-Brexit plan of establishing a ‘global Britain’, adoption automation in the metalworking industry will likely be a deciding factor, given the wider manufacturing industry’s reliance on metal goods for their own production needs.

“But at the organisational level, companies must look to automation to bolster agility, productivity and competitiveness - before automation inevitably plays an even more fundamental role in operations.”