The potency of remote maintenance and customer assistance – especially harnessing the power of ‘smart’ phones - has never been demonstrated more forcibly than during the past year with the Coronavirus pandemic forcing world-wide lockdowns.

However, the

United Grinding Group has increasingly used technology to support its global customer base and, in many cases, keep machines running with minimal downtime.

According to United Grinding Group company

Walter Ewag UK, the Group’s digital solutions embrace three main offerings for the users of member companies’ wide range of grinding solutions; Production Monitor, Service Monitor and Remote Service.

The first two help customers keep track of production - for example, highlighting when maintenance work is required and where/when problems may arise in production. Remote Service is designed to help support the help desk over a data connection. But why use this route rather than simply telephoning the help desk?

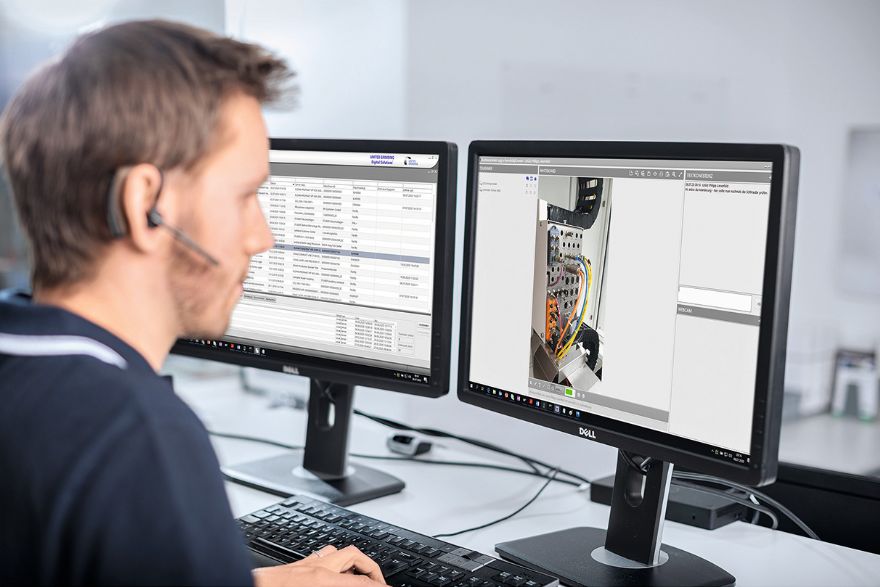

Neil Whittingham, sales director at Warwick-based Walter Ewag UK, said: “Technical enquiries on the telephone without image support can be very lengthy. That is why the United Grinding Group has integrated our established Conference Center into Digital Solutions. The Conference Center app has now been redesigned so that we can reach customers via their smart phones.”

One example of Remote Service in action concerns the machine’s back-up battery. This maintains the power supply of a control system in the event of a power failure and it must be changed from time to time.

The machine operator receives a notice on the operating panel in a timely manner, and the production manager would also see this on the Production Monitor. The user manual and installation instructions are available to both of them via the Customer Cockpit but they can also send a service request directly through the Digital Solutions app.

The service technician will be connected live via the Conference Center and will be able to be provided with tips and hints. Images can be sent via the whiteboard function and the helpline technician can draw markers directly into the images.

Mr Whittingham continued: “There were 2,500 demands for remote service during 2020,” who adds that United Grinding North America also performs preliminary machine acceptances remotely.

“The application team produces videos of the required processes by mounting a GoPro camera in the machine, using a time code to document the duration of the relevant process cycles.”

Other digital tools are also being worked on, including smart glasses. These offer a number of benefits including the fact that the technician at the machine can have his hands free while the help desk specialist also shares the same view. An extension of this would be the application of contextual information via augmented reality.

The use of technology to help customers remotely does not only apply to repair and maintenance; remote process optimisation is also a possibility, using data from the Production and Service Monitors. That would effectively create a full circle of digital solutions for the United Grinding Group and its customers.