When faced with the need to find high-precision, ‘flexible’ measuring devices that would satisfy the inspection needs of two divisions of Birmingham-based

AM Hydraulics, development engineer Stuart Hill discussed each division’s requirements with

Faro Technologies UK Ltd in Rugby and requested demonstrations of suitable portable CMMs.

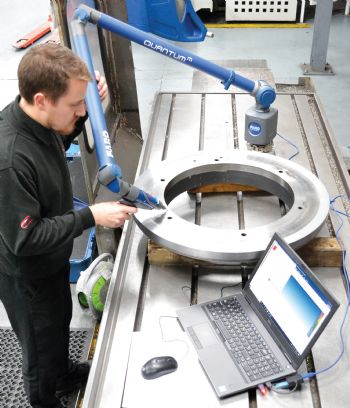

He subsequently decided that the speed and capacity of Faro’s QuantumM 3D ScanArm would be the optimum portable inspection solution for AM Hydraulics’ large components, with the recently launched Faro Gage measuring arm for the relatively smaller workpieces of the company’s AM Tooling division — thanks to its accuracy, quick set-up and ease-of-use abilities. Both Faro products were ordered.

Established in 1978, family owned AM Hydraulics is based in a recently opened purpose-built facility and has grown to be a ‘major force’ in hydraulics manufacturing, serving sectors that include aerospace, nuclear power, earth moving, oil and gas, and wind power, offering ‘end-to-end’ production capabilities that include milling, finish grinding and hard-chrome plating.

AM Hydraulics is ISO 9001 accredited and an approved supplier to many blue-chip companies, so the quality of its output is of paramount importance. In addition to undertaking final inspection routines, quality inspectors also make detailed in-process checks at every stage of production. Given the size of AM Hydraulics’ workpieces — up to 3,000mm in diameter and weighing as much as 20 tonnes — administering an efficient in-process quality regime presents a range of challenges.

The Faro QuantumM ScanArm now being used by AM Hydraulics is certified to ISO 10360 -12:2016 (the ‘most rigorous’ international measurement quality standard in existence); and in addition to performing efficient tactile inspection tasks it can also undertake non-contact scanning routines when used in conjunction with a FaroBluTM Laser Line Probe HD.

Faro’s next generation of blue-line laser technology, it enables five-times faster scanning than previous models and can be used on complex surfaces comprised of dark and reflective materials.

Moreover, when compared with its predecessor, the QuantumM ScanArm is ‘20% lighter in the hand’; and as it requires no warm-up time, it is always ready to use.

Meanwhile, the use of wireless connectivity and dual ‘hot swappable’ batteries supports the Quantum M ScanArm’s data transfer capabilities and its continuous operation in remote areas of the factory floor without the need for external power.

Mr Hill said: “Given the size of AM Hydraulics’ large workpieces we chose a QuantumM ScanArm with a ‘2.5m capacity’; and because it is easily transportable and both quick and simple to set-up, our operators can carry the system to all of our production areas and quickly put it to work carrying out detailed inspection work using its touch probe or its non-contact laser probe.

“In addition to delivering the levels of speed, accuracy and capacity we were looking to achieve on our large parts, the QuantumM has significantly reduced our inspection data-capture times. Our staff are now able to instantly download collected data, store it directly onto a computer and compare it against nominal CAD data.”

Equally challenging, although different in scale, are the inspection requirements of the AM Tooling division, which specialises in the design, manufacture, assembly and repair of press tools.

Explaining the use of the recently purchased Faro Gage (it has a ‘1.5m working volume’ and a volumetric accuracy of 0.022mm), Mr Hill said: “Our use of the Faro Gage has not only speeded up AM Tooling’s inspection work and flow of data but also enabled us to increase our capabilities regarding precision.

“Also, its high level of application flexibility has helped us to lessen our reliance on hand tools such as calipers and height gauges while reducing the use of numerous measuring instruments spread around our shopfloor.”

He concluded: “Our two new portable inspection technologies provide us with a major advantage over the use of a fixed CMM, as we not only use them for final inspection purposes but also to perform in-process checks on workpieces that remain fixtured in machine tools.”