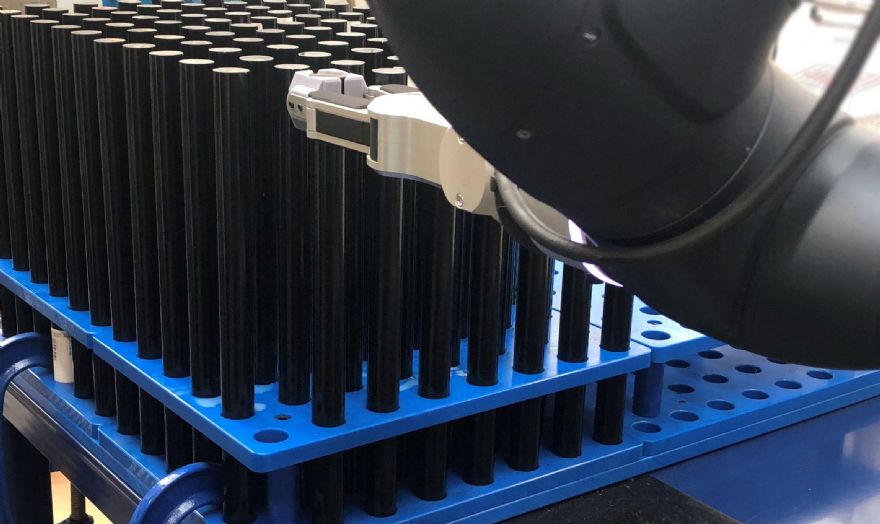

The M1013 cobot picking parts at McCallum Bagpipes

The M1013 cobot picking parts at McCallum BagpipesA leading bagpipe manufacturer has boosted its productivity and capacity following a recent decision to investment in its first collaborative robot (cobot) supplied by

Mills CNC Automation, the exclusive distributor of Doosan collaborative robots in the UK and Ireland.

McCallum Bagpipes Ltd - the largest bagpipe manufacturer in the world has purchased an M1013 cobot, which features a 1,300mm reach radius, 10kg payload capacity, six high-tech torque sensors for safety and collision protection, and comes with RG6 OnRobot gripper end-effectors.

It was installed in the manufacturer’s 6,000ft

2 machine shop in February by

Engineering Supply Co (Scotland) Ltd, an independent distributor and supplier of engineering consumables based in Glasgow and agent for Mills CNC Automation in Scotland.

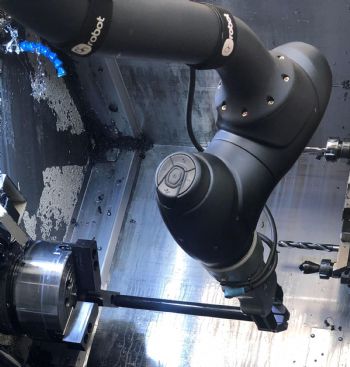

The cobot has since been put to work undertaking machine tool-tending operations — loading workpieces that require machining into a CNC lathe and, after the machining operations have been completed, unloading the machined parts into containers, before repeating the cycle.

McCallum Bagpipes’ managing director Stuart McCallum said: “Since being installed the cobot, in a relatively short space of time, has significantly helped us improve our productivity and operational efficiencies.

“By integrating the cobot with our Dugard ‘Eagle 200’ CNC lathe we are able to operate this machine 24/7 — running it unattended and overnight. The results have been remarkable.”

The performance and productivity gains being achieved by the company are clearly evident in the following example relating to the automated machining of a medium batch of practice chanters — the integral part of a bagpipe that resembles a recorder — made from Polypenco (plastic).

Practice chanters (100 off) are placed in a plastic tray situated adjacent to the lathe and the cobot. Each chanter sits vertically in its own, individual circular hole.

The cobot is programmed to open the machine door — take a designated chanter, in sequence, from the tray — orientate it — and place into the machine’s open chuck. which then closes.

The cobot then moves away from the machine — the machine door closes and the chanter is machined. Once the machining operation has been completed, the door opens and the machined part is removed from the machine and placed in a container.

Part cycle time, including all cobot and machining operations, is short - typically 3min in total.

Mr McCallum said: “We can load up jobs like this late at night during our late shift. The 100 practice chanters are machined to completion overnight and unattended in approximately 5hr (20 parts machined per hr).

“As well as getting 5hr unmanned production from the machine, the cobot investment also means that operators are no longer required to perform repetitive and tedious part loading and unloading tasks, and owing to the short cycle times, be virtually at the machine’s beck and call.”

McCallum Bagpipes, established in 1998 and employing 38 people at its facility in Kilmarnock, is on a strong growth trajectory with revenues and profits up, year-on-year, over the last five years.

This growth, fuelled by the company’s innovative product development and imaginative marketing strategies, has seen the company significantly increase international sales, as well as consolidate its market-leading position in the UK and Ireland.

With markets as far afield as Canada, the USA, Europe and the Middle East - and with a growing product portfolio that now includes Breton and uilleann/Irish pipes as well as more traditional Highland and Scottish small pipes, demand is at an all-time high.

While clearly being good news for McCallum Bagpipes — the consistent upsurge in demand did put pressure on the company’s existing manufacturing resources.

Mr McCallum explained: “To ensure quality and cost-competitiveness very few of our manufacturing processes are ‘subbed out’. But despite running a two-shift system we were still under pressure. We needed to become more efficient and optimise the technology we had at our disposal.”

As part of McCallum Bagpipes’ continuous improvement programme the company, at the beginning of 2021, began exploring automation.

He added: “Things crystallised and fell into place during a conversation with Engineering Supply Co (Scotland). They introduced us to cobots and, being the agents in Scotland for Mills CNC Automation, to Doosan cobots in particular.

“In addition, I did my homework, talked to more people and looked at a number of YouTube videos to understand the strengths, weaknesses and potential of the technology - and how it could be applied at McCallum Bagpipes. In truth I didn’t need that much convincing.”

The M1013 cobot acquired by McCallum Bagpipes now operates 24/7 - Monday to Friday. It has been permanently integrated with one of the company’s 20 CNC lathes and, after only two days required for its installation followed by a further two days to train four members of staff, the cobot was up and running.

Mr McCallum concluded: “We are delighted with the investment. Not only have we been able to ramp up productivity and get more out of the Dugard lathe it is attached to, we have also been able to significantly free-up our operators’ time — it’s a real win-win situation.

“We estimated a payback period of four years for the cobot. With this type of return on investment, plus the marked improvements it has made to our productivity and efficiency - we will certainly be investing in a second cobot in the not-too-distant future.”