Abrasive wear can be extremely damaging – it can change the critical dimensions and tolerances of a component, cause machinery and equipment to rapidly deteriorate in performance, and ultimately cause machine failure and productivity loss.

For end users looking to reduce the effects of wear and abrasion, there are now standard components made from ceramics specifically designed for the task available from Birmingham-based

Norelem.

High-performance ceramics are becoming increasingly important, especially in manufacturing. Due to their properties, a longer life cycle can be achieved and a wide range of requirements can be met.

Ceramic materials are temperature-resistant and made with hygienic materials, so are not only suitable for mechanical engineering, but also for the automotive industry, the food and pharmaceutical industry and circuit board manufacturing.

Furthermore, the technical ceramics market is forecast to grow 9.3% annually between 2020 and 2027 due to the demand for durable and high-temperature resistant materials.

Be ‘weary’ of abrasionWear is the progressive loss of material from the surface of a solid body as part of mechanical processes, for example, contact and relative movement of a solid, liquid or gaseous counter body. Meanwhile, abrasion is the removal of material through furrowing and scoring stress.

There are two basic forms of abrasive wear: two-body abrasion and three-body abrasion. A simple description of two-body abrasion would be a hard, rotating surface cutting into a soft, fixed surface. Three-body abrasion can be explained as a hard particle moving between two surfaces.

If the wear of a component is not recognised in time and it subsequently breaks or fails, damage can also occur to adjacent parts and machinery - resulting in unscheduled downtime and production grinding to a halt.

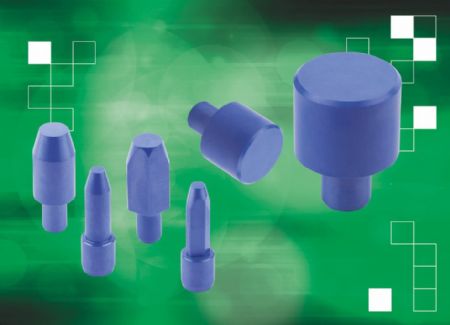

Difficult operating conditions or very long turnround intervals can lead to severe wear on the surface of the components if the correct material is not being used. For example, locating pins, which are frequently used in the positioning of metal sheets, are exposed to increased abrasion within special operating conditions. Progressive material removal when inserting the sheets can influence the positioning accuracy of the fixture, requiring ceramic material to be used.

Consider ceramicsThe use of ceramic products often results in competitive advantages, after all the positive properties are endless: the high dimensional stability, flexural strength and wear resistance to name just a few. Components made of high-performance ceramics operate with high precision, showing almost no signs of wear even under heavy use.

In many applications where the robustness of the components is important, the use of components made of high-performance ceramics is worthwhile. The higher procurement costs are more than offset by the longer service life. Ceramic also has a thermal and electrically insulating effect. This is an advantage in all applications where there is a risk of electric breakdown.

High-performance ceramics feature a low adhesion tendency in contact with metals, providing a longer life cycle of the component if mixed with metal counterparts.

The robust material of ceramics is also a good choice for applications with high mechanical loads due to its high flexural strength and hardness. Thanks to the mechanical strength and low density, tools made of ceramics work precisely, reliably and are wear-free over a long period of time, even under the highest loads.

Ceramic products are also food-safe and offer high resistance to acids, alkalis and vapors. They are generally insensitive to chemicals, are pressure-resistant and temperature-stable and thus defy frequent and intensive cleaning processes or maintenance. This makes them ideal components to use in food and beverage and healthcare industries, where chemicals and acidic solutions are present.

Avoiding abrasion with standard componentsIntroducing ceramic standard components into a design process also brings another benefit – it allows an increase in operating temperatures if needed, potentially speeding up the production process and creating more components in a shorter timeframe.

The issue of corrosion is also dramatically reduced when it comes to ceramic standard components, meaning machine parts need to be serviced and replaced much less frequently due to the durability of the component. Especially for demanding applications, engineers should not shy away from the higher prices - components made of high-performance ceramics literally ‘pay off’ in the medium and long term.

Wear and abrasion are a constant challenge for the manufacturing industry, with a wide range of environments that machine parts and components must endure, therefore engineers have numerous material considerations before production kicks off.

Designed to endure the harshest environments, Norelem’s comprehensive range of ceramic products have been developed with service life in mind. Even under high levels of mechanical stress, the company’s ceramic components are highly robust and suitable under extreme conditions, helping engineers extend the life of their machines.

With more than 60,000 standard components, Norelem offers an extensive range of parts, which includes ceramic.