With its latest HX5 grade incorporated into the ‘NTK CeramiX’ range, the Japanese cutting tool manufacturer has launched the ‘ultimate’ ceramic grade for finishing hardened materials.

NTK Cutting Tools, which has a UK base in Hemel Hempstead, has introduced the new HX5 grade to not only match the performance of CBN but also to provide cost savings when undertaking hard turning applications. Suitable for the continuous machining of materials with a hardness of 55 to 65HRc, the new TiAlN coating on the HX5 inserts offers excellent wear resistance.

The new grade is capable of machining at a cutting speed of 100 to 200m/min and at a feed rate of 0.07 to 0.5mm per rev. As a finish turning grade for challenging material types, the new HX5 grade from the ‘NTK CeramiX’ range is suitable for machining at depths of cut from 0.1 to 0.5mm, breaking the boundaries of speed, feed and performance.

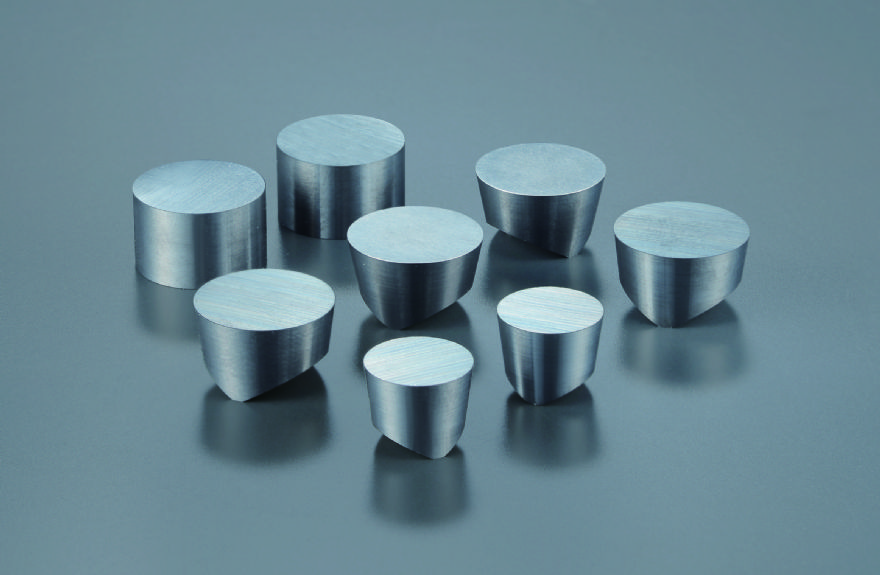

The new grade is available with four different geometry deviations, the CHGA, DNGA, VNGA and the triangular TNGA. All four variants are available with a choice of a 0.4, 0.8 and a 1.2mm corner radius that prolongs tool life while maintaining a robust cutting edge.

Each insert geometry is 4.76mm thick with the CNGA and DNGA inserts incorporating a 2.7mm IC (indexable insert) whereas the TNGA and VNGA designations have an IC of 9.35mm.