Alloyed

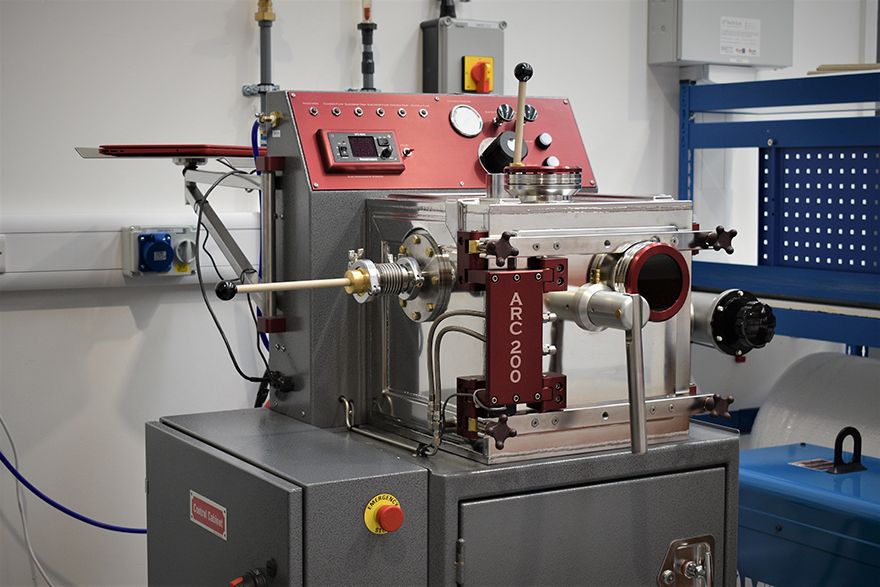

Alloyed (formerly OxMet Technologies) encompasses the brands Alloys-By-Design (ABD), Betatype, and Alloyed Digital Manufacture (ADM), enabling it to optimise advanced digital metal manufacturing applications. The company recently bought an Arcast Arc200 arc melting furnace, which has been installed at its Oxford-based Rapid Alloy Research Centre.

The installation of the arc melter follows in the footsteps of an electro-thermal mechanical testing (ETMT) machine and adds significantly to Alloyed’s in-house ability to work on an array of AM and non-AM metal product applications.

Gael Guetard, the director of Alloyed’s Rapid Alloy Research Centre, said: “Alloyed is expert in the development, licensing, and manufacture of proprietary alloys, alloy powders, and alloy components for a growing number of industry sectors.

The acquisition of the Arc200 means that Alloyed is one of only a few private commercial companies to have this technology in-house. It has been purchased to complement our two induction melters installed in 2020; these have been key assets for our copper, nickel, platinum, iron, and aluminium alloy development projects.

“The induction melters use a ceramic crucible that reacts with some alloys and are limited to 2,000°C, whereas the Arc200 has a copper crucible that accommodates higher melting point alloys and means we can now produce alloys with high levels of Ti, Zr, Nb, Ta, Mo and W — for example — significantly widening the markets and customers we can reach, particularly in the medical, space and nuclear sectors.

“Before we purchased the Arc200, we would outsource the melting of high-temperature and reactive alloys, but this had the knock-on effect of increasing the cost and lead times of our projects — and meant that we had little control over quality. Bringing this capability in-house means that we can significantly increase the pace of our alloy development projects and gain more control over the quality of the alloys.

“The new arc melter in our research centre allows ingots to be cast and subsequently characterised and tested. While we are currently in the commissioning phase, we already have several new alloys lined-up: Ti-based alloys for medical applications, bulk metallic glasses for jewellery, high-entropy alloys for gas turbines, refractory-based alloys for space — and more.”