Republic of Ireland-based

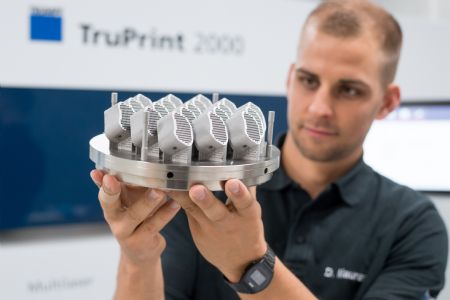

Smithstown Light Engineering has invested in a Trumpf TruPrint 2000 3-D printing system, at its facility in Shannon, to further enhance its support for the country’s medical device sector.

The first machine of its type to be installed in the country, the TruPrint 2000, supplied by Bedfordshire-based

Trumpf Ltd, is now busy producing prototypes and samples for a variety of customers in 17-4 and 316 stainless steel.

Founded in 1974, Smithstown Light Engineering started out with a workforce of just four skilled toolmakers. During the early 1990s, the company moved towards specialising in medical device manufacturing and has never looked back.

Today, the company employs 141 people across three sites, two in Ireland and one in Poland, focusing on the provision of precision-engineered medical device and orthopaedic instrument/implant solutions, typically for hip and knee replacement procedures and cardiovascular delivery devices.

Already offering a range of manufacturing capabilities, including milling, turning, grinding and EDM, Smithstown was keen to add 3-D printing to its repertoire, and set about creating an additive manufacturing centre within a recently constructed 30,000ft

2 extension.

Managing director Gerard King said: “We worked for two years with IMR (Irish Manufacturing Research), a technology and research organisation, to experience 3-D printing and get a feel for what it could do in terms of its capabilities, limitations, advantages and disadvantages.”

The aim was to provide an additive support role for Smithstown's medical device customers, specifically with regard to R&D work. Manufacturing engineer Kevin Kelly explained: “We looked at many potential machines, before designing our own benchmark and sending it to suppliers of interest.

“It was the quality of the benchmark produced by Trumpf, using its TruPrint 2000, which caught our attention. In addition, the volume of the machine was perfect for our needs and the price was competitive.”

Installed at the end of 2020, Smithstown is using the machine to produce 3-D printed parts from metal. The company’s new Additive Centre also houses a machine for printing polymer components.

Mr Kelly added: “AM is ideal for medical work because of the complex geometries involved. Without 3-D printing, several processes would be required, taking many hours. It also offers the potential for individual customisation, which has obvious benefits for products such as implants.

“In the medical sector it can take years to move from the design and test stage, to validated production, but we are now in a position to help speed up this process and bring customer ideas to life. Upon reaching the production phase of current projects we could well need several 3-D printing systems so that we can dedicate machines to a single material. We will not hesitate to invest in more machines if the demand is there.”

With its small 55µm diameter laser beam, the TruPrint 2000 provides a high-quality printing result that impresses with its surface quality and level of detail. Two Trumpf 300W fibre lasers deliver high productivity over the entire cylindrical build volume of 200 x 200mm.

Among notable options that help to ensure the highest quality standards is melt-pool monitoring. With this function, deviations in the laser metal-fusion process are detectable early via sensors, and critical areas of the component can be visualised.

Users can also monitor all weld pools in parallel. Moving forward, Smithstown's business strategy is to focus more on high-volume precision components, rather than simply tooling and small-batch parts.

Mr Kelly said: “Some of our competitors have 3-D printers, but the TruPrint 2000 definitely gives us an edge. Furthermore, we have a dedicated team of experts who can design parts specifically to leverage the benefits of AM, thus helping to minimise costs without compromising quality. Designing a 3-D printed part is quite different to designing one to be machined traditionally.”

Smithstown — which carries certifications that include ISO9001 (quality), ISO13485 (medical devices) and ISO14001 (environmental) – has recently secured several new projects and is looking to recruit new people to meet the demand.

Mr King concluded: “We are really happy with the quality and build speed of the TruPrint 2000, which is backed up with good support from Trumpf – they have listened to our needs throughout. As a result, we have not experienced any unexpected issues whatsoever, which is impressive considering this is our first venture into AM.”

Trumpf will demonstrate its 3-D printing systems at

TCT3Sixty, taking place from 28 to 30 September at the NEC, Birmingham. Visitors to stand F28 will see first-hand how 3-D printing systems are shaping the future of manufacturing. Trumpf offers laser technologies for metal AM from a single source – laser metal fusion (LMF) and laser metal deposition (LMD).

Different industries and components have varied requirements, which is why Trumpf offers such flexible production solutions. New to the range is the TruPrint 3000 3-D printing system – production set-up can be easily adapted to the requirements of the customer or the application.