A team led by engineering firm

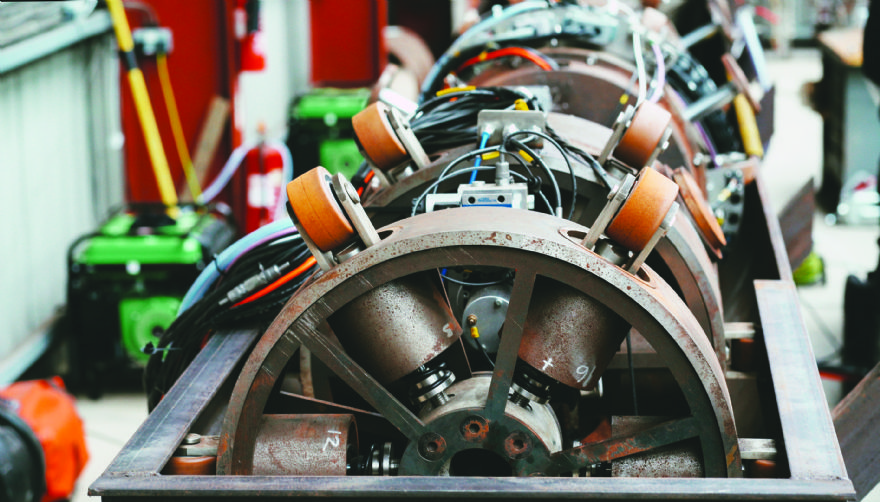

Forth has worked for the past two-and-a-half years on the development of FSWBot, an ‘innovative friction-stir-welding robotic crawler’ designed for the internal repair and refurbishment of pipelines. The team is now looking for assistance to help bring the working prototype to the commercial stage.

It is being developed to travel hundreds of miles down an oil pipeline, scan for any defects in the structure, and carry out subsequent repairs — all as oil continues to flow, and while being controlled remotely by engineers at a safe distance from the pipeline.

This process will remove the need for divers to work on pipelines and for oil production to be halted, therefore saving significant time and money — and removing humans from hazardous environments.

The FSWBot can ‘walk’ to the exact point of a defect, place a ‘milling patch’ in place and then weld the problem area. Forth has produced a concept model of the FSWBot and successfully demonstrated the prototype to a consortium of partners at its headquarters in Cumbria.

The Innovate UK-backed project has also been supported by partners TWI, Joining 4.0 Innovation Centre (J4IC, a partnership between TWI and Lancaster University), Innvotek and London South Bank University.

Chris Downham, Forth’s programme manager, said: “An exciting opportunity to bring such a pioneering piece of kit to the commercial stage now exists, and we are keen to hear from anyone who may be interested in helping us get to the final stage. In order to improve on the working prototype and assist with the commissioning process, we would like to work with partners who would be interested in helping develop such innovative technology.

“This is a world-first piece of equipment and it will have a major, positive impact on the oil and gas industry, ensuring oil pipeline repairs are carried out more safely, quicker and without restricting production. It is a great opportunity for partners to be involved in something that will change the way the industry works across the world.”

The FSWBot will be a five- or six-segment ‘PIG type’ that will be inserted at the production end of the pipeline and will flow with the oil to a pre-designated area, where it will stop and perform the repair work. One segment will carry the FSW machine and a steel patch dispenser, with other segments carrying the navigation, control system, communications, NDT and power storage/generation payloads.