Mills CNC

Mills CNC, a machine tool supplier based in Leamington Spa, has chosen to use a laser triangulation sensor from

Micro-Epsilon UK Ltd in one of its bespoke machine tool automation cells.

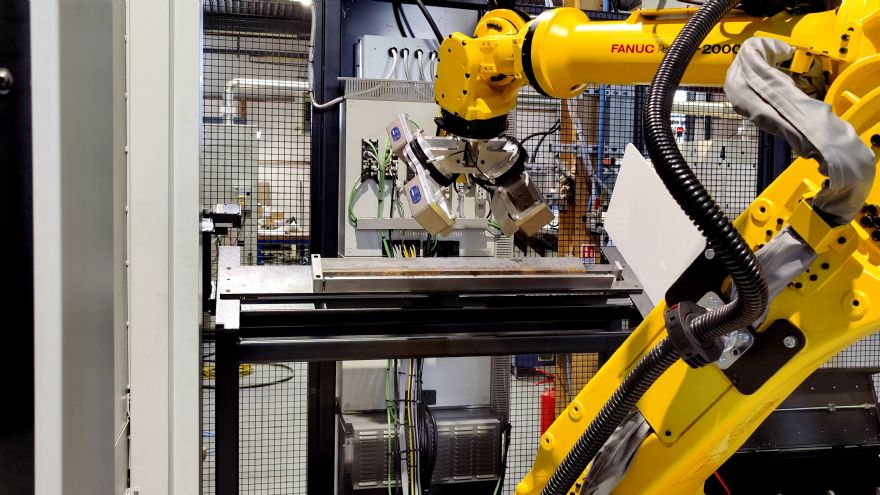

The triangulation sensor, which is mounted on a Fanuc robot end effector, measures the contours of large hot-rolled steel railway fishplates to ensure they are within the required manufacturing tolerances. The automation cell then places the fishplates into a Doosan Mynx 5400 vertical machining centre to be machined.

Mills CNC saw automation as key to increasing manufacturing productivity and output for all customers, and in 2018 established Mills CNC Automation. This division has two principal specialisms — industrial robots and collaborative robots.

Chris Ingham, a controls and systems engineer at Mills CNC Automation, said: “At the Technology Campus we have developed a number of automation systems and machine tool demonstrations for our customers to view. We are currently testing and commissioning an automation system for a customer that needs to inspect railway fishplates prior to machining.

“There are four different product groups that vary in length from 0.5m up to 1.0m. Mills CNC Automation has custom designed and built a fully automated machine tool pick-and-place system for inspecting the fishplates.”

The OptoNCDT 1750 laser triangulation sensor from Micro-Epsilon is mounted on a robot end effector in between two magnetic grippers. The laser sensor measures the fishplate in eight different positions and outputs this data via the Micro-Epsilon IF2030 EtherNet I/P module into the Fanuc robot controller.

This data is then used by Mills CNC’s own custom analysis software and the results displayed on the machine tool HMI. The data is used to verify that the fishplates are within tolerance in all three planes, including whether ‘bend’ and ‘twist’ tolerances have been exceeded.

Mr Ingham added: “If the measurement data shows that a fishplate is out of tolerance, the part is rejected before machining and returned to the rolling mill. The fishplates need to be within a tolerance of 2mm over a length of 1m, but we needed a sensor that was reliable and capable of communicating with our Ethernet I/P network. These factors, as well as a favourable price-performance ratio, were critical for us when searching for a suitable sensor solution.”

The OptoNCDT 1750 is a laser triangulation sensor with integrated controller that can be easily mounted on a robot end effector. It is also suitable for high-speed distance, displacement and position measurements in a wide range of applications, including automation, machine building, electronics production, packaging, automotive and process manufacturing. Mills CNC is using a sensor with a measuring range of 750mm.