One of the UK’s leading suppliers of cutting tools, oils and lubricants has joined forces with a tech spin-out from the

Advanced Manufacturing Research Centre to accelerate the adoption of ‘smart factory’ data analytics to improve machining shopfloor productivity.

Bedford based

Carillon Industry Services (CIS) Ltd, which supplies precision engineering companies across the south of England and beyond, is partnering with Sheffield-based

FourJaw Manufacturing Analytics. The latter’s cloud-based app and ‘clip-and-play’ MachineLink hardware provides immediate real-time access to machine utilisation activity on the shopfloor.

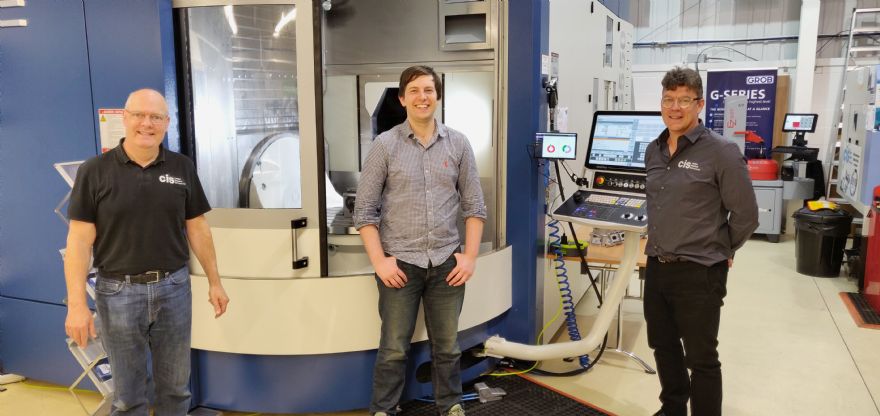

Bryan Clover, CIS owner and managing director, was developing an Industry 4.0, smart factory concept as part of the firm’s CNC analytics offer when he discovered tech start-up FourJaw which is just celebrating its first birthday following VC investor funding in 2020.

When FourJaw’s founders – Chris Iveson and Robin Hartley – visited the ‘state of the art’ CIS Productivity Proving Centre, they saw an immediate fit with Bryan’s Smart Factory offer to his customers across the aerospace, defence, medical and automotive sectors.

Mr Clover said: “Our mission has always been to add significant value to our customers by equipping them the right cutting tools and oils for the job. The FourJaw platform is a different type of tool that enables manufacturers to eliminate unwanted downtime and maximise productive time. It fits perfectly with our smart factory concept.”

Mr Iveson, FourJaw’s CEO, added: “This partnership is a natural fit for FourJaw because Bryan and his team at CIS share our vision of revolutionising manufacturing using simple but transformative technologies to maximise productivity.

“Everyone has heard of Industry 4.0 and Made Smarter; our partnership turns both those ideas into practical, affordable real time applications. This will enable the precision engineering firms who CIS supply with tools, oils and lubricants to maximise the outputs from their capital investments.”