Cambridge Precision

Cambridge Precision, a high-precision engineering firm that employs 80 people at its St Neots base, has invested £1 million in robotic technology that will help boost production and improve working conditions for its engineers.

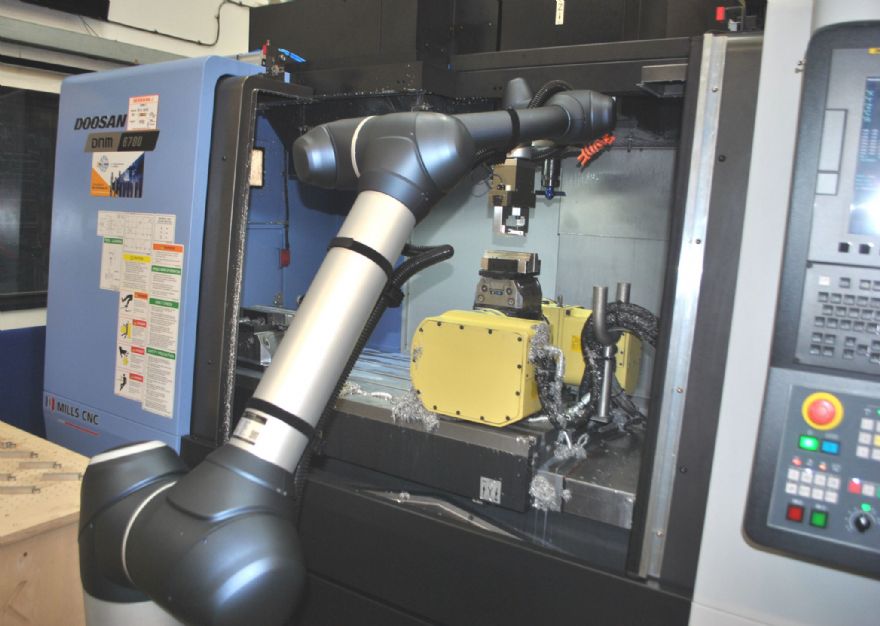

The firm, which was founded in 1994 and designs and manufactures small-scale critical components for global clients in pioneering sectors such med-tech, imaging, security and life science, has integrated two Doosan collaborative robots (cobots), supplied by Leamington Spa-based

Mills CNC to create an automated manufacturing cell.

The new cobots remove the repetitive tasks involved in the high-precision production process, enabling Cambridge Precision’s team of skilled engineers to focus on the more complex elements of manufacturing and assembly.

Nick Raven, Cambridge Precision operations manager, said: “Our investment in the two cobots, which our staff have named Rodney and Derek, has certainly increased productivity.

“The predictable manual tasks can now be performed 24/7 by the cobots, with as many repetitions as necessary to get the job done, while our staff who would have had to carry out those fairly supervisory processes can be getting on with much more interesting and creative work that is outside the remit of cobots.”

He added: “Technology is integral to the ‘state of the art’ manufacturing environment we have created here at St Neots and plays an integral part in the milling, turning and quality checking of the components we manufacture.

“The cobots represent the next step in our ongoing investment in technology that enables Cambridge Precision to work alongside those innovators that are developing critical technologies. That focus is also helping us to win back business to the UK that had previously been lost to overseas manufacturers, by providing expertly engineered, quality products that are swiftly produced and competitively priced.”

Cambridge Precision designs and produces specialist components for clients in a range of high-tech industries, from med-tech to forensic imaging, producing components for the likes of airport security machines and robotic surgery. It supports its clients from concept development and manufacturing of prototypes through to large-scale machining production.