Walter

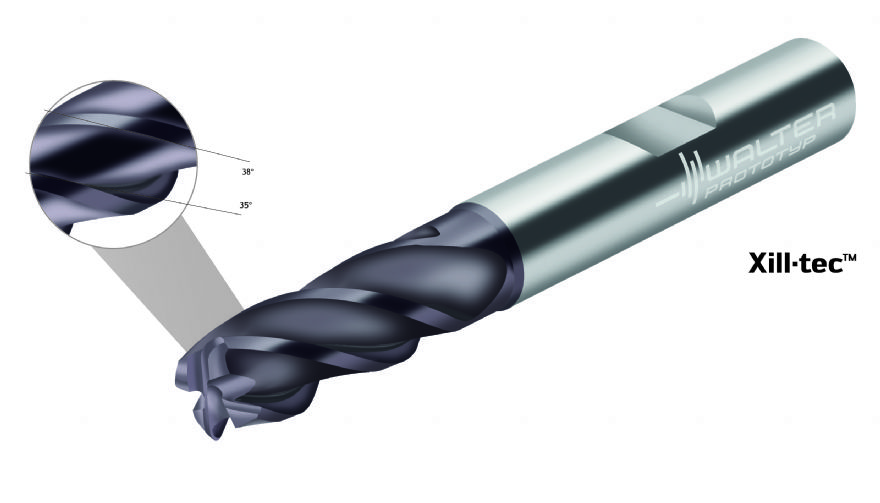

Walter is expanding its Xill·tec range with the introduction of the new MC230 Advance solid-carbide milling cutters. The new end mills demonstrate a high-performance geometry with an asymmetrical helix (35deg/38deg) that has been combined with Walter’s innovative wear-resistant and high-performance WK40TF grade.

The result is a family of universal high-performance tools for rough and finish machining. Walter have consolidated the developments of the past ten years into the Xill·tec range and the result is an asymmetrical helix — the most important feature of geometry as it enables smooth, vibration-free operations.

This is essential for extending tool life and process reliability. Fractures are avoided and the high level of operational smoothness contributes to the soft cutting action and low cutting forces generated by the Xill·tec milling cutter.

The new high-performance milling cutters are suitable for all ISO material groups (P, M, K, N and S) and cover all common milling operations. This includes everything from shoulder milling, ramping, (helical) plunging and full slotting up to 1xD.

The impressive performance levels and material removal rates are also achievable when undertaking innovative machining strategies such as dynamic milling. The Xill-tec MC230 end mills are available in diameters from as small as 2mm through to 25mm and depending upon the chosen diameter, the Xill·tec MC230 is available with corner radius options up to 4mm. The corner radius options prolong tool life and extend performance levels during heavy material removal applications or when machining challenging materials.

The comprehensive range also contributes to the universal applicability of Xill·tec. The milling cutters are available with a variety of options that includes centre cutting edge, reduced neck for enhanced stability, protective chamfer, cylindrical and Weldon shank and also with and without corner radii.