Divergent Technologies

Divergent Technologies, which has been ‘applying the power of additive manufacturing (AM) to unleash innovation in the automotive industry’ and implement economical serial production, has developed its ‘state of the art’ Divergent Adaptive Production System (DAPS) — an end-to-end digital manufacturing platform that uses ‘a data-driven method to design and print structures and components for vehicles’.

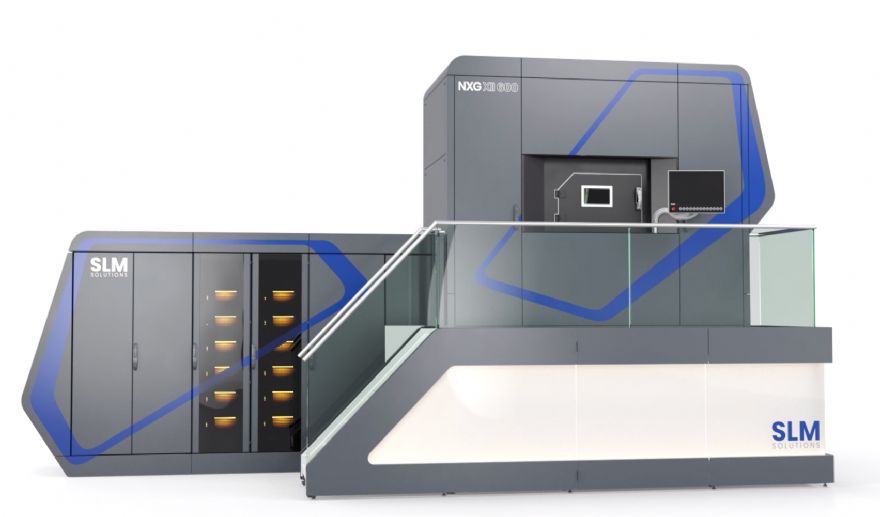

The capability this system offers will now be strengthened with the addition of three production SLM NXG XII 600 systems, following a development partnership with

SLM Solutions Group AG) — a manufacturer and developer of Selective Laser Melting metal AM systems that has its headquarters in Germany and offices worldwide.

SLM Solutions and Divergent Technologies entered a Joint Development Partnership in 2017, and for the past 1.5 years Divergent has been operating with three of SLM Solutions’ pre-production systems at its US facility in California.

The three additional NXG XII 600 systems will bring Divergent’s installed base for this printer to six, making the company the largest ‘shareholder’ of this model in the USA. This new fleet of NXG XII 600s will join Divergent’s current installed base of seven SLM500 systems, three SLM280 systems, and one SLM125 system.

Production of complex structuresKevin Czinger, Divergent’s founder and CEO, as well as a supervisory board member of SLM Solutions, said: “The purchase of the SLM NXG XII 600 is the culmination of years of intensive joint development that completes the shift from prototyping to the production of complex structures.”

The SLM NXG XII 600 is equipped with 12 lasers (each rated at 1kW), making it the ‘fastest machine on the market’, being capable of printing at speeds up to 20-times faster than that of the current ‘state of the art’ single-laser systems; and with a build envelope of 600 x 600 x 600mm, it can manufacture both large and consolidated components and many smaller components ‘in a single digital step’.

Sam O’Leary, SLM Solutions’ CEO, said: “The NXG XII 600 is designed to be used in serial production for high-volume applications, as well as for printing large parts, making it the ideal choice for advancing Divergent’s unique digital manufacturing platform for the automotive industry.”

Divergent’s initial factory deployment will involve the production of ‘thousands of tons of complex, automatically assembled structures’, which will be hitting the road over the next two years.

This will be followed by the scale-up of its advanced facilities, specially designed for sustainable production using DAPS, which will begin with the fully homologated Czinger Vehicles 21C hypercar, which Czinger describes as being “created by a team of designers, engineers and scientists using a revolutionary Human-AI production system that integrates automated design and optimisation software, patented additive manufacturing-driven processes, high-accuracy automated assembly, and novel performance materials”.