Norsk Titanium completes full-scale article testing with GA-ASI

Posted on 07 May 2022. Edited by: John Hunter. Read 1788 times.

Norsk Titanium US Inc

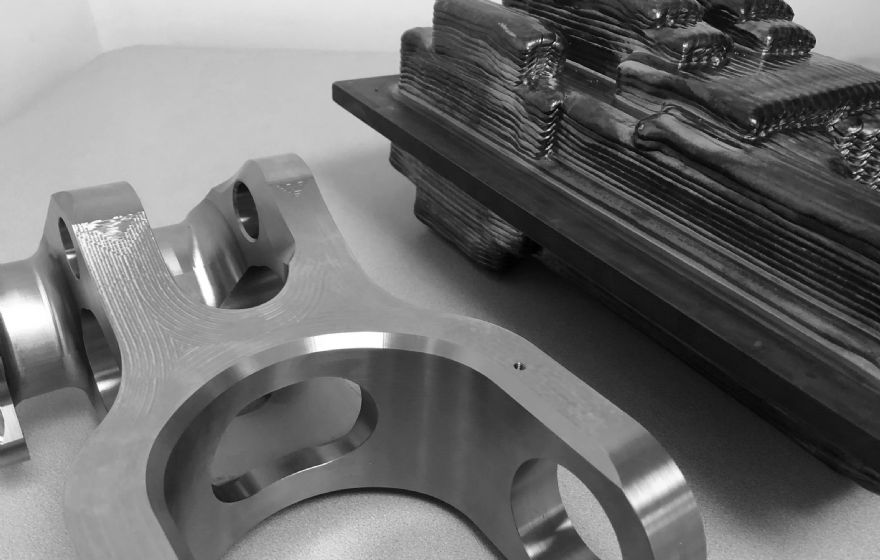

Norsk Titanium US Inc, a global leader in metal 3-D printing through its Rapid Plasma Deposition (RPD) technology, has announced successful component level testing with

General Atomics Aeronautical Systems, Inc (GA-ASI).

Started in 2021, the test programme explored the application of Norsk Titanium’s RPD technology in significant structural applications for GA-ASI products. The preliminary test results for the selected landing gear component indicated promising performance.

This effort was performed as part of Norsk Titanium’s expansion into the defence market with Norsk Titanium US producing the test component using their patented RPD additive technology. GA-ASI additive and structural engineering teams conducted inspection and functional load testing as well as material testing.

Testing was conducted in support of the GA-ASI mission to enable and accelerate additive manufacturing technology integration into their design and manufacturing operations, processes, and products maximizing the buy-to-fly ratio benefits for GA-ASI and their customers.

Nicholas Mayer, Norsk Titanium vice president (commercial), said: “We would like to thank GA-ASI for their support of our technology and the additive industry in general. We believe there is a good fit for our technology in GA-ASI applications that traditionally call for long lead time forgings. Our team is ready to support GA-ASI as it continues its qualification process and further develops its DED additive applications.”