Chesterfield-based

Seal Team Systems creates bespoke leak repair systems works for a wide range of customers, including food manufacturers, energy generators, water suppliers and hospitals, to provide on-site leak sealing technology to minimise any disruption or downtime, which can be expensive or even life-threatening.

The leaks that they rectify can be anything from 150psi steam in industrial/hospital scenarios, through to super-heated steam at over 1,000psi (70 Bar) at temperatures up to 700degC. Time is therefore critical in manufacturing a range of components that combined can create an effective leak repair that can be made permanent at the next scheduled maintenance shutdown.

With every on-site leak posing different problems, the parts manufactured by Seal Team Systems are truly bespoke; with the process starting with a customer-site visit by a trained technician who reviews the problem, takes detailed measurements, with manufacturing starting on his return to the factory.

All of this can take two-three days, a situation compounded by a reliance on manual machining, a time loss that is unacceptable to many customers, with one quoting an eye-watering £3 million cost for a three-day shutdown.

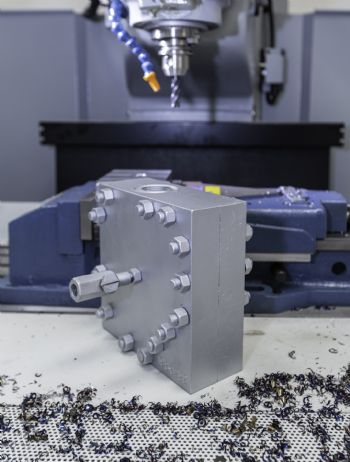

To address this, Seal Team Systems has invested in an XYZ RMX 5000 bed mill fitted with the latest ProtoTRAK control system supplied by Devon-based

XYZ Machine Tools. Andy Mills, Seal Team Systems director, said: “We recognised a need to automate the process as much as possible, especially as finding the skilled people to create the parts we need was becoming harder.

“With the XYZ RMX 5000 the technician, who was also the machinist, can now simply text all the details to us and we can start machining straightaway, turning what was a 2-3 day process into a next-day service.”

The XYZ RMX 5000 is the largest machine in the ProtoTRAK bed mill range and is equipped with a 7.5hp programmable and variable speed spindle, with three-axis CNC provided by the user-friendly touchscreen ProtoTRAK control. With a table measuring 1,930 x 356mm and axis travels of 1,524 x 596 x 584mm it is large enough to handle most jobs.

TRAKing facilityA key feature for Seal Team Systems is the TRAKing facility built into the control which allows operators to use the handwheels to move through the CNC program, at a speed they are comfortable with, even allowing for the program to be reversed if necessary. Once happy the cycle start button can be pressed and the control takes over completely.

Ken Black, Seal Team Systems director, said: “The move to the RMX 5000 with the ProtoTRAK control was a logical step up from manual machining, the training was straightforward, and we were operating it very soon after installation.

“The time savings we are now making are significant, and typically amount to a 66% reduction in lead times. Being new to CNC we were also impressed with the support given by XYZ Machine Tools.

“Prior to ordering we had a number of demonstrations, where we brought our own difficult-to-machine materials, XYZ also modified the showroom machine to provide air cooling to the cutter, rather than coolant, which was our preference — nothing was too much trouble.”

The arrival of the XYZ RMX 5000 also brought other changes to Seal Team Systems with an investment in Autodesk’s Fusion 360 CAD/CAM software. Mr Black continued: “With the XYZ RMX 5000 we are able to machine parts we couldn’t attempt before on our manual machines, including out of round/oval parts such as valve bonnets.

“This has opened up new possibilities for us and the software package allows us to be more creative and make use of Finite Element Analysis, meaning we can give added reassurance to customers and avoid over-engineering parts as has happened previously.”

Business for Seal Team Systems was good prior to the arrival of the XYZ RMX 5000, but since then it has seen an increase in turnover and the company is looking for additional people to handle the extra workload being generated.