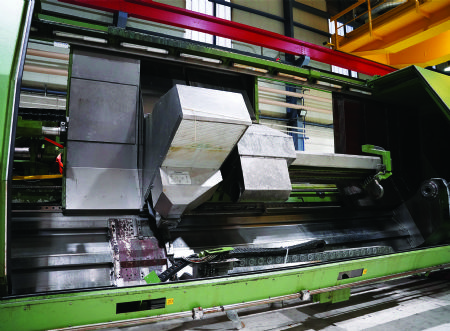

In autumn 2021, and using ‘oversized transportation’, an M150 Millturn from the Austrian machine tool manufacturer

WFL — represented in the UK by

Kyal Machine Tools Ltd, Market Harborough — was installed at V-NASS in Ostrava, a city in the north-east of the Czech Republic and about 15km from the border with Poland. The machine is 16.5m long and weighs 60 tonnes.

Discussing some of the reasoning behind the machine purchase, Pavel Krpec — director and chairman of V-NASS — said: “The oil and gas industry has been in an ongoing crisis for several years, which is pushing prices for suppliers to the limits of economic viability.

“Maintaining one’s market position at a time when production of simple components is increasingly being moved to countries with lower labour costs means focusing on complex production processes that require comprehensive solutions. However, when the project to increase our capabilities began, the Millturn wasn’t a machine we had in mind, despite its multi-function capabilities.

“Originally, we had been considering a single vertical turning machine and a single horizontal turning machine — and possibly a five-axis machine for milling operations in the future. As it transpired, a WFL M150 Millturn machine was available and combined all our current and anticipated future requirements.

“It was a pre-owned model that WFL had taken in and rebuilt; the company had also improved the specification — including an automatic U axis that allows face plates and D’Andrea heads to be applied for precision drilling and turning operations.”

Because the prevailing market conditions meant it was not a good time to be making large investments, it was not easy for V-NASS to convince its parent company the benefits a machine such as the M150 Millturn could offer, but its specification, along with its combination of functions and performance proved to be a strong argument.

Last year, representatives from V-NASS took the opportunity to see a similar, albeit smaller machine — a medium-size M80-G Millturn — that WFL had recently installed at T-Machinery (this is a major production and engineering company in the field of mining technology and currently one of the few producers in the Czech Republic that can design, manufacture, supply and put an entire mining complex into operation).

Mr Krpec said: “Seeing what a machine can do in practice is, of course, the best option for any engineer. We were able to do this here, with a practical demonstration of the machine’s technology and capabilities.”

Advanced machiningV-NASS has now added to its machine portfolio with an advanced ‘machining centre’ that can undertake turning, milling, drilling and counter boring; and thanks to additional modifications, further capabilities such as five-axis-milling, shaping and deep-hole drilling can be undertaken. Moreover, the machine also has an exchange system for milling heads and other adapters using the prismatic tool interface.

This M150 Millturn machine, which is the second-largest model from WFL in the CEE region, can process workpieces up to 6.5m long, 1.5m in diameter and weighing up to 15 tonnes, thereby enabling V-NASS to undertake larger and more-challenging machining projects.

Mr Krpec added: “Put simply, we can produce bigger and more complex parts with greater added value. Previously, our machines didn’t allow for the production of large parts, but now that is changing. Together with our operators’ skills, we can produce technically challenging parts with complicated features, as well as gear teeth and deep holes — on a single machine.”

During the preliminary acceptance of the machine at the WFL manufacturing plant in Linz, a ‘completeness check’ was carried out by machining a sample part and then carrying out deviation measurements.

Zbyněk Ludačka, managing director of Ludačka Machine Tools — a sales, service and technology partner to several leading European machine tool manufacturers, including WFL — said: “The machine fulfilled the geometric and all other requirements, with the performance values at the level of a new machine. When machining the sample part, all deviations in size and position were in the range of 3-6µm for the 36 measurements.

“There are not many used machines with this level of quality and technology. They rarely come onto the market and the systems are generally 20 to 25 years old, which is why the WFL’s decision to now focus more on used machines is very welcome, as it allows us to offer customers in the Czech Republic and Slovakia an attractively priced, reliable machine with the full support of our service team and a manufacturer’s guarantee, which sets us apart from dealers with used machines.”

Mr Krpec had soon assigned the new machine its first task: “We have an interesting order from General Electric, which was a challenge for both our programmers and operators — as well as for the WFL teams. To put it very simply, now all the customer has to do is ensure that the workpiece fits in the machine — the machining quality will always be perfect.”