As part of the global launch of the next generation AddForce cutting tools from Cannock-based

Tungaloy UK, the manufacturer has launched the new AddForceCut range of grooving and parting-off turning tools. The impressive new series introduces an optimally designed self-clamping technology that demonstrates exceptional rigidity for enhanced performance.

The new insert clamping design from Tungaloy has a stopper that supports the underside of the insert to guarantee edge position, security and repeatability. Furthermore, this new design spring clamps the insert with three contact faces to maximise this level of stability. The result is smooth uninterrupted chip flow that is a credit to two variations of effective 3-D chipbreakers.

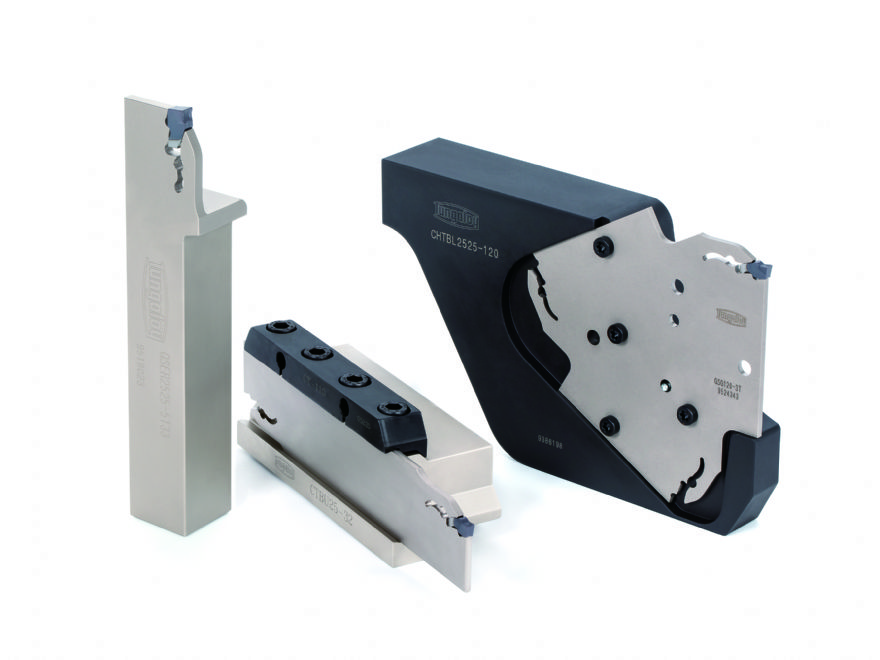

To maximise the potential of this new line, Tungaloy has developed the series with four toolholder options, an interchangeable blade system with toolholder, the TungFBlade with a triangular interchangeable blade design that accommodates three inserts, a solid single insert toolholder and also a modular head system for cutting at 90deg.

The QSP blade system for deep grooving and parting is available with 150mm long blades that have widths of 1.8, 2.4, 3.2 and 4mm depending upon the seat size selected that ranges from 2 to 5mm. The blades are provided in heights from 26 to 32mm with a depth from the insert tip to the base of the blade from 21.1 to 24.4mm to optimise the rigidity and strength of the system when parting-off larger diameter parts.

The QSER toolholder blocks for clamping single inserts are available with block sizes of 20 by 20mm and 25 by 25mm and an overall length of 125 or 150mm to suit all turning centre configurations. The QSER holders can also accommodate insert widths from 2 to 5mm with clearance for cutting at depths up to 26 to 33mm depending upon the selected toolholder.

Alongside the QSER and QSP holders is the impressive TungFeed-Blade type toolholder, a triangular blade that accommodates three inserts and a design that maximises strength and rigidity to accelerate machining performance. This system clamps the blade with two contact faces to demonstrate unparalleled stability. The toolholder support is significantly thicker than typical blade systems and this further minimises deflection and chatter when cutting at high speeds and feeds.

The AddForceCut series is available with two insert geometries, the QGM and QGS that are provided with Tungaloy’s AH7025 insert grade for machining everything from steel and stainless through to cast iron and superalloys. Both coated insert geometries are provided with seat sizes from 2 to 5mm with an insert length of 11 or 13mm depending upon the selected toolholder.