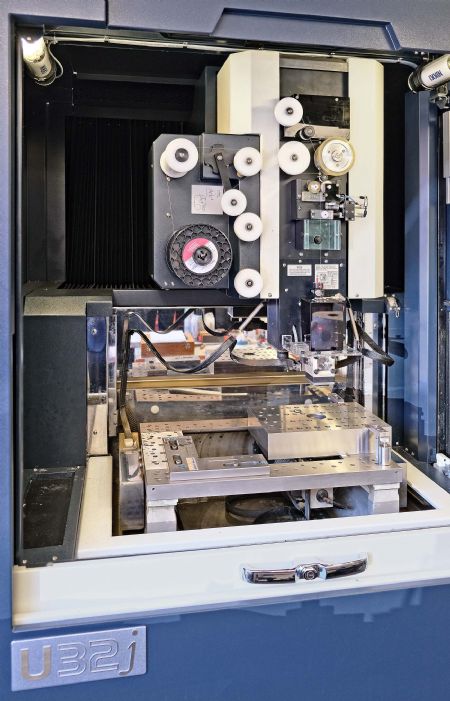

The Makino U32j wire-cut EDM machine on the shopfloor at BM Injection. The twin-screen control with HyperConnect remote connectivity to the mould maker’s Open Mind CAM system is shown on the top screen; below is Makino’s process control screen

The Makino U32j wire-cut EDM machine on the shopfloor at BM Injection. The twin-screen control with HyperConnect remote connectivity to the mould maker’s Open Mind CAM system is shown on the top screen; below is Makino’s process control screenEstablished over 30 years ago, the mould maker

BM Injection operates from a 10,000ft

2 manufacturing facility in Whitchurch, Hampshire. Out of every 10 moulds produced, eight are used for on-site production of injection-moulded plastic products for sectors that include aerospace, automotive, domestic appliance, sports, safety, optics and transportation.

Before it is complete and ready for use, every mould visits both a die-sink and a wire-cut electric discharge machine (EDM) — plus a machining centre for hard milling. The proportion of time spent on each machine varies depending on the mould design; all three machine types used for manufacturing the moulds were built by Makino in Japan and supplied through sole UK agent

NCMT Ltd, Thames Ditton. That said, some hard milling is also undertaken on an Okuma three-axis machining centre on-site.

The latest machine to be installed, in May 2022, was a U32j wire EDM fitted with the same Hyper-i control system as the Makino EDAF3 Heat EDM die-sinker that arrived in 2019; a Makino D200Z five-axis machining centre was installed at the same time.

The Hyper-i — a Windows-based twin-touch-screen CNC system with an intuitive interface similar to that found on tablets and smartphones — includes advanced functions to support operators of all skill levels at every step of the machining process. For example, an extensive library of cutting conditions that automatically optimises the erosion process, even for sealed and poor flush applications.

The control also enables easy access to and selection of power settings to produce accurate results in the shortest possible cycle times; and it features HyperCut technology, a process developed by Makino to produce surface finishes as fine as 3µm Rz in standard tool steels in a three- or four-pass process.

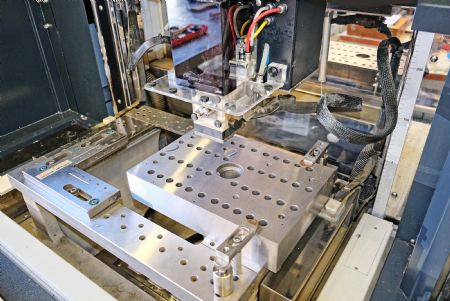

High-accuracy capabilityThe machine ordered by Mark Combes, a director of BM Injection, was a high-accuracy package with 0.05µm scale feedback capable of producing extremely smooth surfaces down to 0.7µm Ra if a seven-pass process is used.

Mr Combes said: “With a wire machine it is all about producing sharp radii and smooth surfaces, especially on the interior of ejector pin holes. That is exactly what the U32j has produced right from the start due to a combination of rigid machine build, thermal stability and the Hyper-i control. We knew this software would deliver, as it had proved itself on the EDAF3 machine we installed three years ago.”

Mr Combes points out that of particular note is the bi-directional HyperConnect Industry 4.0 network connectivity for remote machine monitoring and interlinking of all manufacturing information. “This standard software allows access via the cloud to our Open Mind OptiCAM wire EDM CAM software. The CAD/CAM information occupies the top monitor of the twin-screen control and can be viewed and operated as if it were onboard, while Makino’s process control screen occupies the lower monitor.”

He also mentions the standard Crystal II machining functions built into the Hyper-i control, which are effective for machining shapes that are hard to polish while enhancing surface finish for improved mould release. “No special insulated jigs are required and machining is performed with uncoated 025mm-diameter Bedra brass wire, which has a high zinc content and is the standard consumable used at our Whitchurch facility.

“The U32j can use wire down to 0.07mm in diameter; this is smaller than most machines can accommodate. There will be a need for smaller gauges and the accompanying diamond guides for the future production of our optical industry moulds.”

Enhanced productivityMr Combes also points to a reduction in wire consumption coupled with an increase in cutting speed on every job completed so far on the U32j compared with the nearly 20-year-old wire-cut EDM machine that was replaced.

He continued: “When the time came to install new, modern wire EDM technology, we looked at several options, but decided again in favour of the Makino offering, not only because of the control and its synergy with our die-sink CNC system, but also due to the U32j’s working volume of 370 x 270 x 220mm for a footprint of 2,580 x 3,165mm. We get a very compact machine while gaining an extra 20mm of travel in X, Y and Z.”

Mr Combes also mentions the fixed-table rise-and-fall tank design, which gives access on three sides for efficient loading and unloading of components and for easy cleaning and maintenance. “Reliable unattended running is achieved throughout the night and into the next day, depending on the cycle, helped in part by the automatic, jet-less wire-rethreading system, which uses the X, Y, U and V axes to ‘hunt’ for an optimum cutting restart position with the wire clear of the workpiece surface.”

Another technology from Makino is Protech, a galvanic protection option that prevents rusting and oxidation of steel, carbide and aluminium. By placing an electrode plate in the bottom of the tank and giving it a positive charge, the workpiece is held at a negative potential and constantly attracts positive ions, thereby preventing oxidation.

Mr Combes concluded: “We have always received good back-up from NCMT ever since they delivered, installed and commissioned an Okuma three-axis vertical machining centre in 2016. With EDM technology, extensive product knowledge and being able to impart it to our operators during training is crucial; unless parameters are kept within close limits, machining efficiency can fall off quite quickly, so it is important that our staff know what to keep an eye out for. NCMT’s engineers provided a week’s instruction at the outset and are always available either online or on a telephone for troubleshooting or offering technical advice.”