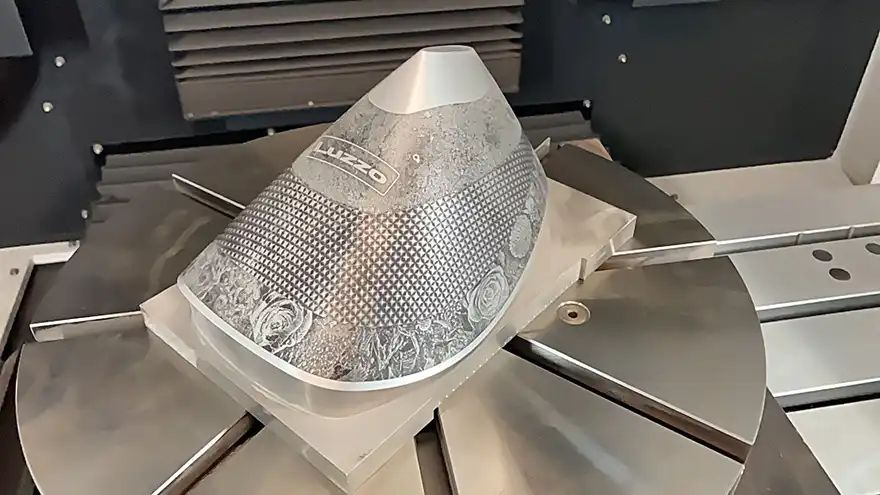

Machined luxury whisky bottle lid made from aluminium with different textures applied to it using the Laser P 1000U

Machined luxury whisky bottle lid made from aluminium with different textures applied to it using the Laser P 1000UNorthamptonshire-based

Luzzo Bespoke, a creative engineering specialist supplying highly customised products to customers in the automotive, marine, life-style and consumer luxury markets, has invested in a new Charmilles Laser P 1000U five-axis digital laser texturing and engraving machine supplied by

GF Machining Solutions, which has since been acquired by the United Grinding Group and is now part of

United Machining.

The new machine, installed in early 2025, at Luzzo Bespoke’s 1000ft

2 manufacturing facility in Brackley, is proving to be transformative — a real technology differentiator that has increased and strengthened the company’s in-house design and manufacturing capabilities, and helped the company expand the range of unique and innovative 2-D and 3-D surface textures it can apply to machined products.

The Laser P 1000U machine’s arrival has not only provided Luzzo Bespoke with a distinct competitive advantage in the markets it serves but, it is anticipated, will also help generate new business opportunities in the future, such as applying high-accuracy decorative and functional textures to mould tools and mould inserts.

The machine is the first laser machine Luzzo Bespoke has acquired from GF Machining Solutions in its 28-year history, although the company is no stranger to GF Machining Solutions’ machine tool technologies, having invested in a number of Mikron five-axis machining centres with integrated workpiece pallet changers in the past.

Brian Challenger, Luzzo Bespoke’s managing director, said: “We have developed good relationships with GF Machining Solutions over the years, and the five-axis machines we have acquired from them previously, starting back in 2001, have helped us increase our productivity and improve our process efficiencies. As a consequence, when we decided to invest in a new laser machine, it was only natural that GF Machining Solutions was top of our list of companies to approach and discuss our requirements.”

Continuous improvementLuzzo Bespoke is committed to continuous improvement and regularly invests in its people, in its plant and equipment, and in its systems and processes as a route to improving quality, reducing lead times and controlling costs.

Being strategically proactive, the company is always looking to keep ahead of the game — searching out, and ultimately investing in, new and emerging technologies that can help it secure meaningful competitive advantage in and across the markets it serves. A recent discussion with a customer helped reinforce the validity of Luzzo Bespoke’s business ethos and approach, and was instrumental in the company accelerating its laser machine tool investment.

Mr Challenger explained: “Not that long ago we were asked to add the finish machining touches to a one-off high-end steering wheel that had been machined in China for a luxury car manufacturer in the UK. The steering wheel was, in truth, machined to high accuracy and certainly looked the part and I estimated that if we were asked to machine the whole job from scratch to the same quality standards, the cost, including the purchase of the raw billet and all associated machining and programming operations, would be in the region of £7,000.

“When I found out that the cost from the Chinese manufacturer was just $950, it reinforced my conviction that competing toe-to-toe on cost with Far East and other low-cost manufacturers was a ‘fool’s errand’, and that, instead, we needed to be offering something new, different and unique to the market, that was valued by our customers, and that could not be easily replicated or achieved by our competitors.”

It was decided that the technology that would help Luzzo Bespoke ‘stand out from the crowd’ would be an advanced five-axis laser texturing machine to meet the company’s immediate and future laser texturing, engraving and ablation requirements.

High-quality productsLuzzo Bespoke designs, manufactures and assembles a range of bespoke, high-quality products. The company’s portfolio of previously completed projects is impressive and diverse, and comprises everything from customised interiors and instruments for concept and one-off cars through to luxury furniture and luggage, and from trophies and awards through to highly sought after backgammon sets.

These products, often described as special and deluxe editions and, limited run, collectors’ items, can be made from a range and/or combination of materials, including metals, plastics, wood, glass and leather, and are manufactured and supplied in low volumes. Luzzo Bespoke works closely with designers, engineers, artists and its customers’ marketing teams, taking and interpreting their initial product concepts and designs and making them a reality.

Design for Manufacturing (DfM) technical consultancy and problem-solving skills, combined with Luzzo Bespoke’s knowledge of different materials, their properties and machinability, and the company’s rapid prototyping capabilities, in-house advanced manufacturing technologies and integrated finishing and assembly operations, ensure high product quality and fast turnrounds.

Luzzo Bespoke is no novice when it comes to laser technology and in 2000 invested in a CO

2 laser machine to etch soft materials including leather, acrylic, and wood veneers. However, this machine with its small working envelope and inability to texture and engrave harder materials including metal, had its limitations and did not eliminate the use of third party suppliers.

Mr Challenger explained: “Sub-contracting work out is expensive and can have a negative impact on quality and lead-time fulfilment. To address the situation and enable us to handle the engraving of metal parts, in-house, we made the decision, back in 2016, to invest in our first fibre laser machine. The investment in this compact, bench-top laser machine was ideal for engraving small metal badges and similar sized parts, but could not easily handle laser engraving on larger workpieces.”

The machine’s limitations were brought into sharp relief when engraving fine details on a large metal plate. The part, which was larger than the machine’s working window, involved a number of clamping and reclamping operations but, despite the company’s best efforts, and the use of an expensive fixture, the engraved detail could not be replicated successfully or to the standard required. The end result was that this part had to be sub-contracted out to a third party.

Since 2022, Luzzo Bespoke has been approached and asked to produce laser textured patterns and details on complex 3-D shaped metal parts with concave and convex surfaces. To achieve the desired effects on such parts it was clear that a five-axis fibre laser, as opposed to a three-axis model, was the way forward. This ‘need’ was the catalyst behind Luzzo Bespoke’s Laser P 1000U investment.

In early 2024, the company approached a number of laser texturing machine tool manufacturers with its requirements. One of the companies contacted was GF Machining Solutions. Initially, Luzzo Bespoke was looking at investing in a smaller Charmilles Laser P 600U machine but, through discussions, it was ultimately decided that the larger Laser P 1000U better met its requirements.

Extremely supportiveMr Challenger continued: “Visits to GF Machining Solution’s facility in Geneva where we could see the laser machines in action and talk directly with the company’s laser product and applications experts were invaluable. GF Machining Solutions were extremely supportive, they liked what we were doing and could see that we would be an ideal, de-facto reference site in the UK for their laser technology. As a result, they offered us a great deal on a new Laser P 1000U and we decided, from a cost, machine specification and availability perspective, to place the order.”

Since being installed, and with training completed, the Laser P 1000U has been utilised for a number of projects. One of these has involved the engraving of titanium legs on luxury, folding directors’ chairs. Because not all of Luzzo Bespoke’s projects have or require a laser texturing or etching requirement, the company has had time to experiment and test the machine ‘to see exactly what it can do’.

The company is currently producing samples and a best-practice product and applications’ portfolio to show new and existing customers the capabilities, possibilities and potential of laser texturing on a range of metals that include titanium, brass, copper, stainless steel and aluminium.

The investment in the Laser P 1000U has not just opened up a whole new world of possible laser textured surfaces for existing customers, it will also be used to help Luzzo Bespoke diversify into new markets, such as the creation of surface textures on mould tools and inserts, the application of functional hydrophobic or hydrophilic surfaces on specific products.

Guarantees high positional accuraciesThe Laser P 1000U is a flexible, large-capacity nano flexi-pulse (50/100 Watt) laser machine equipped with a 380mm B-axis table that can handle large workpieces up to 510 x 480mm in size and 150kg in weight. The machine also features an A-axis -50/+135deg tilting laser head that guarantees high positional accuracies, and is supplied with three lenses that enables the focal length (100/160/254mm) to be adjusted and fine-tuned to suit the application and optimise quality versus speed requirements.

Laser P 1000U machines are supplied with GF Machining Solutions’ powerful and user-friendly software and a sophisticated iHMI that enables customers to quickly master all aspects of the laser machining process — such as job set up (including selection of the desired CAD generated pattern or texture required), material selection and work-piece positioning; laser parameter selection — power, pulse duration and frequency, beam size and shape; laser scanning; and post-processing, including cleaning and inspection.

To improve productivity the machines are also supplied with high-quality tooling reference systems that ensure the delivery of high-accuracies and repeatabilities, and allow jobs to be set up away from the machine. Furthermore, like all GF Machining Solutions’ EDM, milling and laser machines, the Laser P 1000U is equipped with the My rConnect remote machine tool monitoring, diagnostics and assistance system that provides customers with direct and seamless access to a range of GF Machining Solutions’ support services to help improve productivity and ensure machine uptime.

Luzzo Bespoke’s investment in a Laser P 1000U is paying dividends. In addition to completing a number of fee-paying jobs, the machine is also being tested to enable Luzzo Bespoke to show actual and potential customers its potential for producing unique and highly innovative decorative and functional textured surfaces as a route to opening up new business opportunities.